Need help with your application? Contact us for expert advice on AMETEK Drexelbrook level instrumentation.

ABLE are AMETEK Drexelbrook’s Exclusive Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise across the full AMETEK Drexelbrook product range

- Our factory trained engineers offer after-sales support, service and maintenance (contracts available)

- In-depth AMETEK Drexelbrook product training, either in person or via video call

Further to the above, ABLE can offer customised solutions based on your individual requirements. Email us now at info@247able.com

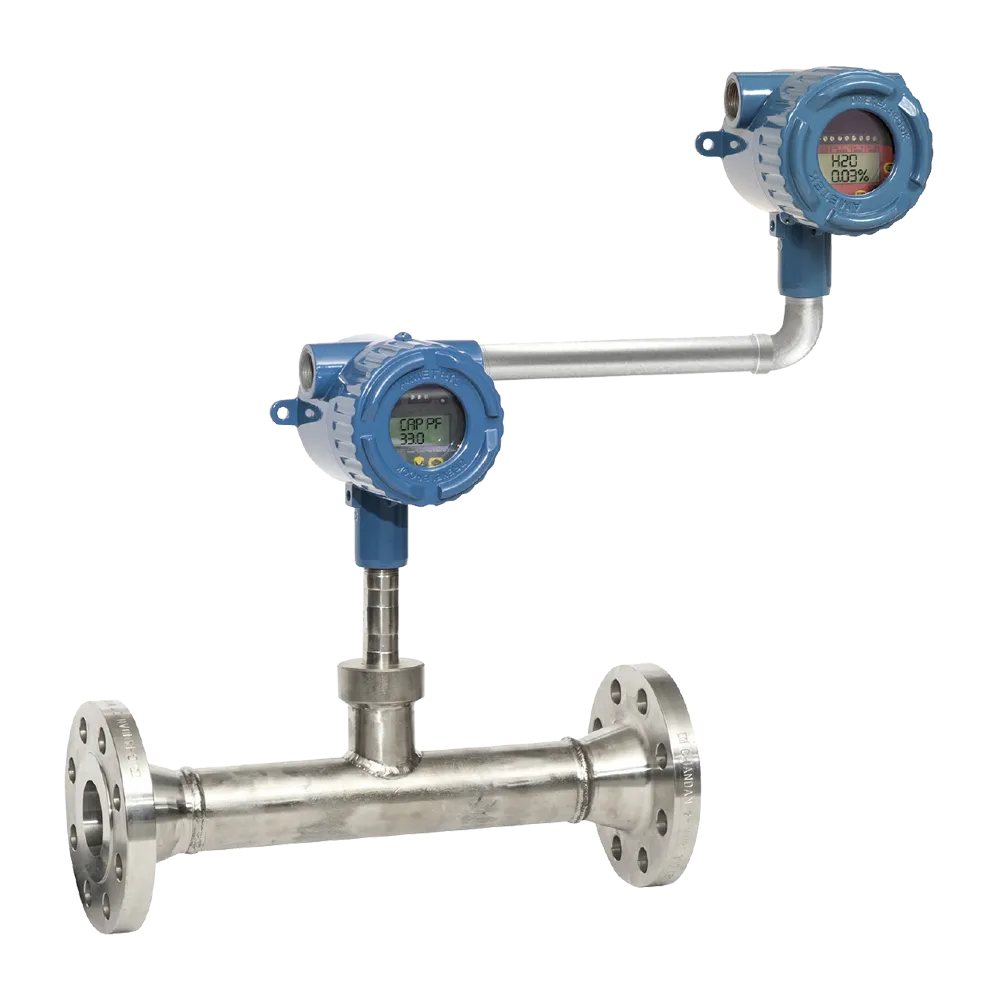

AMETEK Drexelbrook Universal CM Density Compensation Module

Real-Time Density Compensation Module for Accurate Water-Cut Correction

ABLE Instruments are AMETEK Drexelbrook’s Exclusive Representative for Sales and Service in the UK and Ireland, including the Universal CM Density Compensation Module. The Universal CM Density Compensation Module (DCM) enhances the Universal IV and V water cut monitors by compensating for real‑time changes in oil density. Designed to accept input, typically via Modbus, from a customer‑supplied density sensor or Coriolis meter, it adjusts water‑cut readings to account for API gravity variations. This module improves measurement accuracy by up to 50 % over uncompensated systems, minimising false diverts and custody‑transfer errors.

The DCM is available as part of the full “UDO” system or as the “UDR” retrofit module, compatible with existing Universal IV CM installations. It seamlessly integrates without replacing the existing hardware, providing a field‑installable upgrade option. Communication and configuration are managed via the built‑in LCD/keypad or remotely using STExplorer™ PC software.

Key Features:

- Real‑time density compensation: Uses external density or flow sensor inputs to correct water‑cut readings

- Improved accuracy: Up to 50 % more accurate than temperature‑only compensated systems

- Field‑retrofit capable: Available as UDR module or part of UDO system for easy integration

- Simple configuration: Set up using onboard LCD/keypad or STExplorer™ PC software

- Hazardous area approvals: Certified for FM, FMc, ATEX, IECEx, Zone 0 / Class I Div 1 environments

- Robust operation: Performs reliably in challenging industrial conditions

- Minimised downtime: Maintains stable output despite changes in temperature or API gravity

- Seamless compatibility: Fully compatible with existing Universal IV / V CM systems

Have a particular project in mind? We’d welcome a call on +44 (0) 1189 169 420

Built to perform in hazardous environments, the DCM carries the same safety approvals as the primary water‑cut monitor (FM, FMc, ATEX, IECEx, Zone 0/Class I Div 1). It operates reliably at supply voltages from 19–30 VDC and meets industrial emission standards. Its robust design ensures compatibility with existing Universal IV series systems and supports efficient density compensation across varying field conditions.

Universal CM DCM Specifications:

Technology | RF Admittance / Capacitance sensor with external density input |

|---|---|

Supply Voltage | 19–30 VDC, 4‑wire system |

Output / Protocol | 4–20 mA with HART® (via base unit); Modbus input from density source |

Water Cut Accuracy | ±0.03 % @ 0–1 % range; ±0.04 % @ 0–5 % range |

Resolution | Down to 0.0002 % at low range |

Ambient Temperature | −40 °C to +75 °C |

Process Temperature | Up to 232 °C (via base unit compensation) |

Process Pressure | Up to 103 bar (1,500 psi), probe dependent |

Response Time | 350 ms nominal; 1–90 s programmable damping |

Relay Output | SPST, 5 A/30 VDC or 5 A/250 VAC |

Configuration | Onboard LCD/keypad or STExplorer™ PC software |

Approvals | Intrinsically Safe (IS), Explosion Proof (XP), FM, FMc, ATEX, IECEx, CE |