Showing 1–16 of 26 results

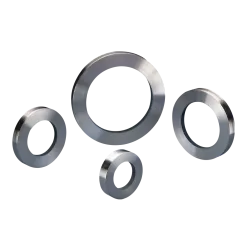

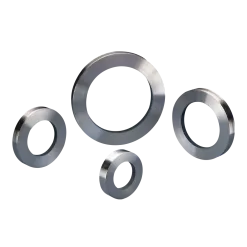

J.M. Canty ANSI/DIN FuseView Industrial Sight Glass

Provides durable, high-pressure fused glass sight windows for safe viewing

Brand: J.M. Canty

P/N: ANSI/DIN FuseView

Lead Time: Contact us for info

J.M. Canty CantyVision Real-Time Viewing / Analysis Software

Provides real-time monitoring, analysis and data output for Ethernet cameras

Brand: J.M. Canty

P/N: CantyVision

Lead Time: Contact us for info

J.M. Canty Crystalscope PAT Liquid Particle Size Analyser

Vision-based system designed for real-time crystal size monitoring

Brand: J.M. Canty

P/N: Crystalscope

Lead Time: Contact us for info

J.M. Canty ExtremeTemp Industrial High Temperature Camera

Provides clear, reliable imaging in extreme high-temperature environments

Brand: J.M. Canty

P/N: ExtremeTemp

Lead Time: Contact us for info

J.M. Canty F700 Series Flanged Industrial Sight Flow

Provides durable, high-pressure fused glass sight flow for process monitoring

Brand: J.M. Canty

P/N: F700 Series

Lead Time: Contact us for info

J.M. Canty FlexView Sight Glass / LED Process Lighting System

Provides high-intensity, maintenance-free LED lighting for sight glasses

Brand: J.M. Canty

P/N: FlexView

Lead Time: Contact us for info

J.M. Canty Float Glass Industrial High Temperature Camera

Provides real-time, non-contact width measurement in float glass lines

Brand: J.M. Canty

P/N: Float Glass

Lead Time: Contact us for info

J.M. Canty FuseView Sugar Pan Sight Glass

Ensures vacuum integrity and safe monitoring in sugar crystallisation

Brand: J.M. Canty

P/N: FuseView Sugar Pan

Lead Time: Contact us for info

J.M. Canty FuseView Tri-Clamp Sanitary Sight Glass

Provides durable, high-pressure fused glass sight windows for safe viewing

Brand: J.M. Canty

P/N: FuseView

Lead Time: Contact us for info

J.M. Canty Glass Wetted FuseView Industrial Sight Glass

Provides a durable, high-purity fused glass sight window for reactors

Brand: J.M. Canty

P/N: Glass Wetted FuseView

Lead Time: Contact us for info

J.M. Canty HYL 52 Series Stainless Steel Sanitary Lighting System

Provides high-intensity, heat-free illumination for sanitary vessels

Brand: J.M. Canty

P/N: HYL 52 Series

Lead Time: Contact us for info

J.M. Canty HYL 80 Series LED Process Lighting System

Provides high-intensity, explosion-proof LED lighting for pressurised areas

Brand: J.M. Canty

P/N: HYL 80 Series

Lead Time: Contact us for info

J.M. Canty HYL Series Fibre-Optic Flex Bundle LED Process Lighting System

Delivers high-intensity, maintenance-free fibre optic illumination

Brand: J.M. Canty

P/N: HYL Series Fibre-Optic

Lead Time: Contact us for info

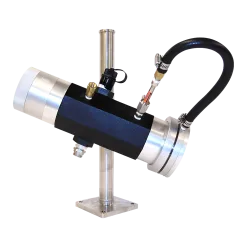

J.M. Canty Industrial Process Camera Systems

J.M. Canty cameras offer real-time vessel monitoring via a 2” NPT port

Brand: J.M. Canty

P/N: Canty Camera Systems

Lead Time: Contact us for info

J.M. Canty Industrial SolidSizer Particle Size Analyser

Provides real-time particle size, shape, and distribution analysis online

Brand: J.M. Canty

P/N: Industrial SolidSizer

Lead Time: Contact us for info

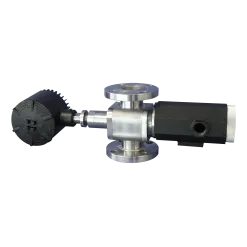

J.M. Canty Inflow Oil In Water / Liquid Particle Size Analyser

Provides real-time in-line measurement of turbidity, colour & solids

Brand: J.M. Canty

P/N: Inflow

Lead Time: Contact us for info