Flow Measurement

ABLE’s stellar reputation for providing solutions rather than just product, was built on its high-end process control instrumentation supply into the heavy industries such as Oil & Gas, Petrochemical and Chemical.

This is particularly true of flow measurement, where the company pioneered the use of clamp-on ultrasonics on refineries and offshore platforms back in the 1990s. Now widely recognised as flow metering experts, ABLE has added V-Cone Differential Pressure Meters, Coriolis Mass Flow Meters, Ultrasonic Flare Gas Meters and Full Profile Insertion (FPI) Magnetic Flow Meters to our process industries portfolio.

It was therefore logical that ABLE’s recently refurbished and enhanced E-commerce platform, 247able.com would feature a range of flow measurement solutions, concentrating, in the main, on low-end devices and those that lend themselves to the more immediate nature of on-line transaction processing. That said, each and every purchase is underpinned by the availability of expert technical advice from our engineering team.

The following is an overview of the flow meter types available from 247able and the applications to which they are suited:

Spinner and Rising Ball Type Visual Flow Indicators – Simplicity Itself

When a Flow Monitor is not required but simple visual confirmation is sufficient, Flow-Mon’s Spinner or Rising Ball Type Visual Indicators are ideal and will satisfy a significant number of applications within pipe sizes 8mm to 25mm.

When operators require a visual verification in their pipework for lubrication and coolant flow, a simple spinner can provide a cost effective solution for plant protection. For example, fitting one of these inexpensive devices to pipework on a power-plant may save thousands of pounds in downtime and bearing or pump impeller replacement.

These flow indicators simply confirm whether or not there is flow or no flow by observing the movement and rotation of the built in “paddle” which is especially useful in situations where it is difficult to ascertain if there is a flow e.g. In a clear liquid. The rising ball type is normally used on gas or air applications where the ball will rise when there is positive flow.

Other applications include:

- Pump, compressor and diesel engine protection

- Ensuring that flow of cooling water is maintained to specialised equipment

- Detecting changes in colour and condition of liquids during processing

- Indication of air entrainment

- Early warning of overheating, bearing or seal failure

Macnaught Oval Gear Oil & Fuel Meters – The New Generation of Positive Displacement Metering Technology

Oval gear meters are displacement-type flow meters that transport defined incremental volumes in individual measuring chambers. The measuring element consists of two high precision toothed oval gears, which are driven by the flow of the medium and mesh with each other. In this way, a defined volume is transported for each rotation of the pair of oval gears. The number of rotations is a measure of the amount of fluid that has passed through the meter. The rotations are detected by a sensor element. Positive Displacement flow meters are the only flow measuring technology to directly measure the volume of fluid that passes though the flow meter. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber.

The Macnaught MX Fuel and Oil series is a range of oval gear flow meters optimised for use in all types of Fuel and Oil measurement applications. Manufactured from solid aluminium billet, and anodised to provide increased protection, this range of flow meters is designed for use in the harshest of industrial environments. Unaffected by variations in temperature, viscosity or pressure the MX range has been proven to provide consistently accurate and reliable measurement of flow. Our Oval gear flow meters are ideally suited to applications requiring the accurate dispensing, transfer or blending of fuels and oils. Measurement of very low flow rates, small batch sizes, pulsating flows, viscous products and non-conductive fluids are all ideal applications for the oval gear flow meter. The high precision and bearing-less PPS rotor design provides exceptionally low pressure drop, making the flow meter suitable for gravity fed applications. This unique rotor design means minimum wear, resulting in many years of reliable service. With only two moving parts, the MX Flow Meter is exceptionally simple to repair. The ability to carry out in-line maintenance, and without requiring any specialised tools or technical personnel, greatly reduces the risk of downtown and loss of production.

Ranging from sizes ¼” – 4”, and suitable for flow rates from 0.5 lph to 1200 lpm, the MX SERIES offers a complete range of 316 Stainless Steel, anodised aluminium and highly resistant plastic flow meters to suit most industrial applications.

Applications include:

- Service and Fuelling trucks

- Fuel Depots

- Portable Fuelling Systems

- Bio-Diesel Blending and Production

- Lubricant Blending and Dispensing

- Hydraulic Fluid Dispensing and Test Stands

- Boiler and Generator Fuel Consumption

- Fuel Consumption for Mining, Construction and Military Vehicles

- Bitumen/Asphalt Production

InFlux Variable Area Flowmeters – Uncomplicated Versatility

Low flowrate Variable Area meters for monitoring, controlling and visualisation in sampling, blending, dosing, aeration, cooling and laboratory and control panel use.

Variable area flow meters are simple, multipurpose devices that operate at a relatively constant pressure drop and measure the flow of liquids, gases, and steam. The position of their float, piston or vane is changed as the increasing flow rate opens a larger flow area to pass the flowing fluid. The position of the float, piston or vane provides a direct visual indication of flow rate. Design variations include the rotameter (a float in a tapered tube), orifice/rotameter combination (bypass rotameter), open-channel variable gate, tapered plug, and vane or piston designs.

247able offers the Uniflux range of direct reading VA flowmeter, combining flexibility, practicality and accuracy for the measurement of gas and liquid flowrates. They are available in standard, compact and long series as well as a range of materials and are suitable for panel or inline mounting. They offer either fine or ultrafine needle control valve options as well as high visibility and ease of installation. A wide range of standard and customised scales are available to meet even the most specific requirements.

For higher pressures and temperatures beyond the practical range of glass tubes, metal tubes are used. These are usually manufactured in aluminium, brass or stainless steel.

Glass VA Meters

Rugged. Economical. Easy to use flow measurement technology When measuring liquid or gas flow at higher pressures and temperatures not suitable for plastic, you can achieve accurate flow rates with robust glass tube variable area flow meters (rotameters) from Brooks Instrument. With a broader range of flow rates available, glass tube rotameters are suitable for a variety of liquids and gases. Plus, the ability to easily see the float and direct flow scales on the tube accommodate a variety of applications, whether in the lab or in industrial processes.

The industry standard glass tube VA flow meter for decades. Multiple material options available for a wide variety of applications. Simple, rugged design for long-lasting performance with low and high-flow gas and liquid applications where viewing the process is important.

- Rugged, single piece frame construction

- Magnifier built into front shield

- Optional needle valves and flow controllers mounted to inlet or outlet for precision flow control

- Standard direct read scales on tube for all fluids and fluid conditions

- Standard millimetre scales with flow curves for all fluids and fluid conditions

- 65mm or 150mm scale lengths

Metal VA Meters

Durable and accurate for high-pressure and extreme temperature applications When Petro-Chemical and Refining customers need high-performance flow meter technology and in-depth technical expertise, Brooks Instrument is their trusted source for reliable, accurate solutions. Our broad line of flow meters, including the MT3750 and MT3809 Series, incorporates key features engineered for tough oil and gas applications:

- Various process connection types (depending on base model): – Threaded – NPT – Flanged – ANSI, DIN, JIS, API

- Option for high alloys (Inconel 625, Hastelloy C, Titanium)

- Special options for high and low temperature applications

- Special MT3809 design for use in high pressure applications up to 20,000 psig (1379 bar)

- Reliable, durable, low flow measurement for long-lasting performance in harsh environments

- Widest temperature, pressure and flow ranges for measuring fluids in hazardous, remote areas

- Compact design

- 4–20 mA output

- Good upgrade from glass tube flow meters

- Optional alarms, transmitters and limit switch controllers provide added levels of measurement and control

- Independent and easily accessible diagnostic/ service port

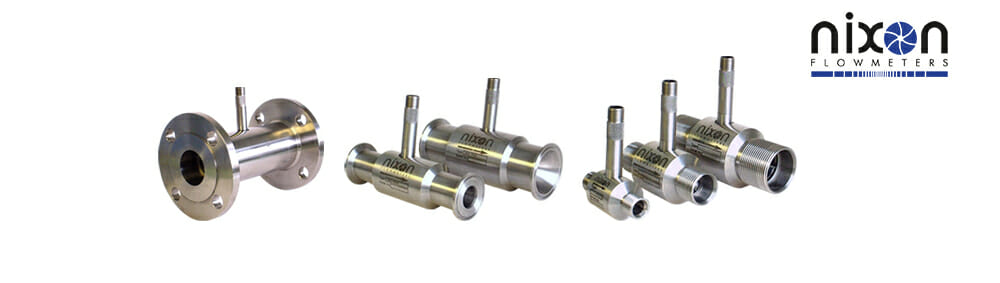

Nixon Turbine Flow Meters

ABLE has been working with Nixon to supply their highly regarded range of turbine flow meters for over 20 years. Some of the advantages of turbine flow meters include: Suitable for both gases and liquids; highly accurate and precise; relatively wide operational envelope; economical to purchase.

NT Industrial Range

Turbine flow meters for use with liquids have a relatively simple theory of operation, as a fluid flows through the tube of the flow meter it impacts upon turbine blades. The turbine blades on the rotor are angled to transform energy from the flowing liquid into rotational energy. The shaft of the rotor spins on bearings, as the fluid velocity increases the rotor spins proportionally faster. Revolutions per minute or RPM of the rotor is directly proportional to the mean flow velocity within the flow tube diameter and this relates to the volume over a wide range.

Available in a wide variety of body sizes, all NT Industrial flowmeters possess an electrical pulse output directly proportional to flowrate. Remote flowrate indication, alarms, totalising and batch control functions are available utilising ABLE’s wide range of secondary electronic instruments.

The flowmeters are suitable for use on lubricating or non-lubricating liquids of low to medium viscosity and are largely insensitive to density variations, pressure or temperature fluctuations.

NS Pelton Wheel Range

NS Pelton Wheel turbine flowmeters are ideal for low viscosity liquids and low flows.

Conventional axial flow turbine meters become increasingly difficult to manufacture in very small sizes and bearing drag becomes more significant. The Pelton wheel on the other hand still retains a manageable diameter allowing close machining tolerances whilst being capable of handling very low flowrates with reasonable accuracy.

The units may be used for additive flows, fuel consumption metering, perfumes, colourings etc and the output is compatible with our standard range of secondary readout instruments.

BNO Hygienic Range

The BNO series flowmeters have been designed specifically for high accuracy flow measurement and batch control in the liquid food industries and conform to the same exacting standards as the NT industrial flowmeters so far as performance is concerned.

In the basic design, Nixon address the particular hygienic requirements of pharmaceutical industries and great care has been taken to ensure the absence of crevices where bacteria can lodge and breed. The materials used in construction ensure that no corrosive attack occurs when in-place cleaning agents are used. Manufactured entirely from stainless steel, except the bearing bushes which are normally of PTFE/Carbon. There are no seals or ‘O’ rings, nor any internal screw threads. Rotors are machined from solid and bearing supports (hangers) are stepped in order to reduce the contact area between hanger and meter internal bore.

The flowmeter may be located some considerable distance from the associated secondary instrument, and remote flowrate indication, total flow, and most important remote batch control are thus possible.

Stand-out features of the BNO Hygienic Range include:

- Minimum of bacteria breeding crevices

- Simple robust design

- Easy one circlip dismantling

- Strong rotor design

- Long bearing life

- Steam cleaning permissible

- Hot detergent Sterilizing permissible

- Excellent repeatability for batching

- Wide variety of end fittings available

Magnetrol Thermal Dispersion Flow Switches

Most people will know Magnetrol for their excellent heavy industry level products, such as their best-in-class Guided Wave Radar and high-performance Magnetic Level Indicators. However, Magnetrol also produce a range of cutting edge thermal dispersion switches, which can be used for flow as well as level and interface applications.

The TD2 is popular for pump protection, specifically low flow detection with the unique spherical tip design, to prevent pumps from running dry. Continuous diagnostics with fault indication, temperature compensation and fast response time make the TD2 the latest in thermal dispersion technology.

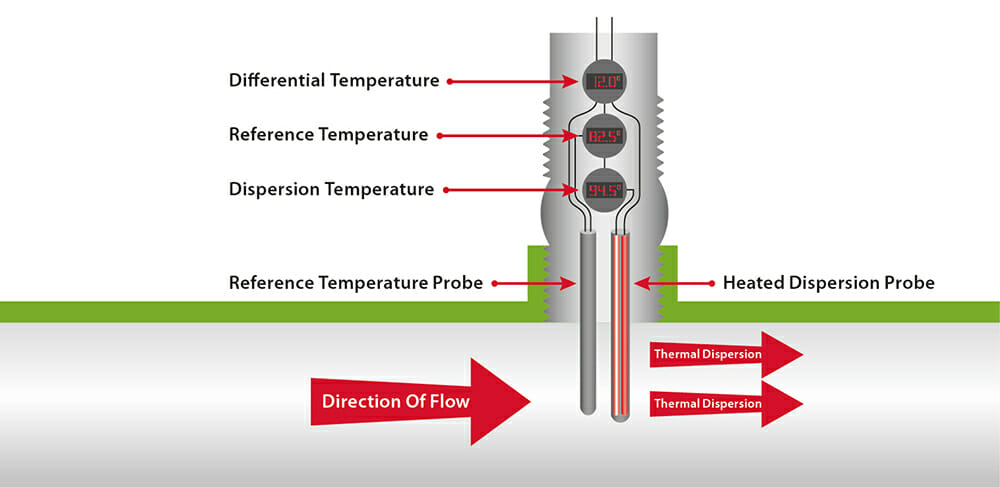

The thermal switches are based on convective heat transfer. The sensor consists of two RTD elements One sensor is at the process temperature and the other is being heated by a constant power. As the flow rate increases, the temperature difference between the sensors decreases. A set point is established so when that specific temperature difference is reached the relay changes state. This can be on either increasing or decreasing flow or flow/no flow. When used in a level or interface application it is primarily the thermal conductivity of the fluid that will provide the difference in heat transfer.

The Model Thermatel TD2 flameproof thermal dispersion switches available from 247able come with ¾” NPT-M stainless steel thermal dispersion sensor and with the option of 5cm or 15cm insertion lengths.

Thermal Dispersion Flow Switch

Thermatel TD1/TD2 switches can easily be adjusted to detect flow (gases and liquids), level or liquid-liquid interface. The TD2 is either V DC or V AC line powered, has integral or remote electronics and offers supplemental LED indication, time delay and mA output for diagnostics and trending. With continuous diagnostics, automatic temperature compensation, narrow hysteresis and fast response time, TD2 represents the latest in thermal dispersion technology.

TD2 – Key Features:

- Easy field calibration – pre-calibration from factory at request

- Variable flow or Flow/No flow detection of gases and liquids

- Excellent low flow sensitivity

- Automatic temperature compensation for repeatable alarm under varying process temperatures

- Sensor fault diagnostics

- Continuous monitoring of flow rate versus setpoint via LED

- mA output provides repeatable indication of flow rate and fault detection

- Optional retractable fitting for dismantling under process conditions

- Process conditions up to +450 °C (+850 °F) and 414 bar (6000 psi)

- Integral or remote electronics up to 150 m (500 ft)

- Unique spherical tip design option ideal for liquids or high viscosity applications

- Suited for SIL1 and SIL2 loops (full FMEDA report available)

TD2 – Applications:

- Liquid or Gas flow detection

- Minimum flow rate maintenance

- Pump protection

- Cooling air/water

- Lubrication systems

- Chemical feed pumps

- Detect presence of flow

- Relief valves

- Flare lines

Ultrasonic Clamp-On Flow Meters

As previously referenced, the application of clamp-on ultrasonic flow meters to the heavy industries, particularly Oil & Gas, was one of ABLE’s foundation stones. Since then, the technology has been widely and successfully deployed into many more industries where the long recognised advantages of clamp-on meters are just as pertinent:

- Simple, low cost installation

- Measurement is independent of fluid conductivity and pressure

- No pressure loss, or possibility of leakage

- Retrospective installation for existing plants possible

- No cutting of pipes necessary, no consequent interruption of process and plant shutdown

- No additional fittings for maintenance required

A highly successful market for the application of clamp-on flow metering has been the BMS/HVAC arena. Modern building management and control necessitate the measurement of thermal energy provided by a source to ensure accurate and proportionate billing based on consumption.

The Micronics range of fixed clamp-on ultrasonic flowmeters, as supplied by ABLE, are widely used in energy management and retrofit building services worldwide. The ULTRAFLO UF3300 brings simplicity to the non-invasive measurement of liquid flow and hydronic energy. Its user-friendly menu and simple set up facilitate fast results.

The UF3300 uses the cross-correlation transit time method for flow measurement and PT100 Class B 4 wire for temperature measurement. Hydronic thermal energy, heat or cooling load is calculated from a combination of the flow rate and the flow and return temperature difference or delta T to comply with EN1434 section 6.

The UF3300 range is able to work with different transducer sets depending on the unit purchased and the application. Optional high temperature sensors are also available. Sensor mounting clamps are provided with each instrument, to ensure correct mounting and reliable operation on any size pipe, in either diagonal or reflex modes.

Micronics also offer a selection of portable clamp-on meters (333 Series) providing exceptional flexibility for the following applications:

- HVAC and energy system audits

- Check system meters

- Pump verification

- Boiler testing, Leak detection

- Filter sizing, Ultrapure water measurement

- Heavy fuel oil metering, Condensate measurement

- Balancing systems

- Clean in place evaluation

- Fire system testing

- Hydraulic system testing

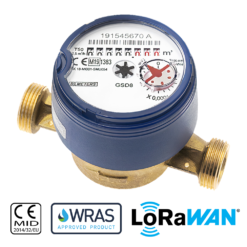

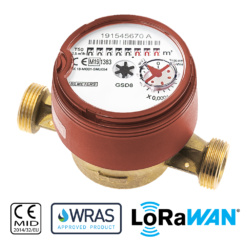

Water Meters

ABLE market the Hydrodigit Smart Meters, Model GSD8 Single Jet and GMDM-I Multi Jet Residential Meters from the B Meter range. All are available in cold and hot water versions in diameters DN15 and DN20mm (1/2” – ¾”) with 360° rotating dials.

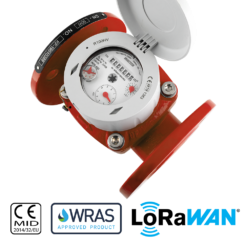

B Meters WDE-K50 Woltmann Type Water Meter

ABLE also offer Woltmann type meters, which are water meters with magnetic transmission and dry recording heads, for measuring applications in potable water, irrigation and industry networks. Available for purchase on 247able.com are B Meters WDE-K50 Woltmann Type Hot / Cold Water Meters with DN50 to DN200 sizes and Q3=40 to Q3=400 m3/hr flow rates.

The standard, domestic water metering market is highly competitive and the strongest emerging differentiators are the new, cutting-edge communication protocols. In addition to M-Bus, B Meters use LoRaWAN, Long Range Wide Area Networks.

Conclusion – Parameters affecting flow meter selection & good installation practice

There are various factors that influence the flowmeter selection for a specific industrial process. Some of those factors are:

- The fluid phase; for example: gas, liquid, steam

- Flow conditions and flow range; for example: clean, dirty, abrasive, or viscous fluid

- Process design parameters; for example, pressure, temperature range, density

- Pipe size

- Accuracy desired

- Material of Construction (corrosive or non-corrosive fluid)

- Repeatability and cost-effectiveness

- Environmental considerations, if any

Installation of Flow Meters

Some form of flow measurement is essential for many industries, so it must provide reliable and accurate data. The accuracy and repeatability of measured data, to a large extent, depend on the correct installation of the flowmeter. Some of the critical steps that must be followed during flowmeter installation are listed below:

- It must be installed in the proper, representative location

- It should not be installed where there are vibrations or magnetic fields

- The flow direction must be known before installing

- Flowmeters should be installed on a straight pipe

- Some flowmeters may need straight length upstream and downstream of the flowmeter. It should be observed for optimum performance

- For liquid flow applications, the downward flow should be avoided

- Ensure that the flowmeter is completely filled with fluid

- Vapour or air in liquid lines and liquid droplets in gas lines should be avoided

- It’s preferable to install a filter upstream of the flowmeter to remove solids

- If repair is required, a by-pass line should be provided

The flow measurement technologies featured above are sometimes referred to as:

Positive Displacement, or “PD” meters; USMs; Time of Flight Meters; Transit Time; Doppler Meters; Differential Area Type; Thermal Mass flowmeters; Helix Meters; Mechanical Flow Meter; Helical Gear; Multiple Jet Meter.

We are on hand to answer any questions you may have regarding Flow Measurement products, please feel free to call us on +44 (0) 1189 169 420 or contact us for a callback. We also offer ongoing product support.