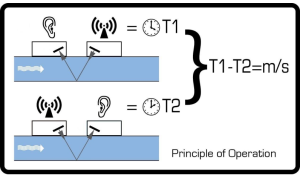

Ultrasonic Clamp-On Flow Meters

ABLE Instruments have been at the forefront of ultrasonic clamp-on flow measurement for over 30 years. With decades of experience in specifying and supporting non-intrusive metering systems, we offer an expert-led portfolio of solutions for both liquid and gas flow applications.

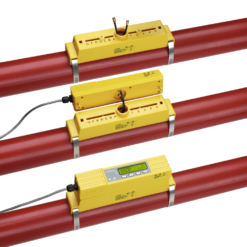

Our first of our flagship products is the Micronics UX5000 ATEX Clamp-On Flow Meter, a high-performance, hazardous area-certified ultrasonic flow meter for liquid measurement in demanding industrial environments. ABLE are the exclusive UK representative for Micronics across the UK and Ireland, ensuring expert application support, technical guidance, and fast delivery. The UX5000 is ideal for petrochemical, water treatment, and process industries where precision and reliability are paramount.

Also available is the ABLE SlugMaster, part of our premium Master Series range. This specialist clamp-on system is engineered to maintain flow measurement integrity in the presence of entrained gas or slug flow conditions. Designed to tackle the toughest flow challenges, the SlugMaster is trusted by process operators where conventional clamp-on meters fall short.

Have a particular project in mind? We’d welcome a call on +44 (0) 1189 169 420 or alternatively, email us now at info@247able.com

ABLE have been at the forefront of Clamp-On Technology for over 30 years. Learn more.