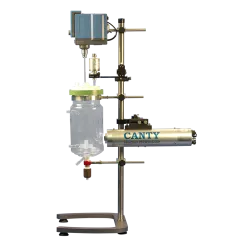

A key feature of Canty liquid particle size analysers is their ability to operate in-line or in a laboratory setting. In-line monitoring enables continuous real-time analysis, which is particularly beneficial in industrial processes where immediate feedback is needed to make process adjustments. This real-time monitoring helps improve efficiency, reduce waste, and ensure consistent product quality. In laboratory applications, Canty analysers provide precise and reproducible data, allowing for detailed studies of particle behaviour in different liquid formulations.

The Canty liquid particle size analysers are also known for their versatility. They can manage a wide range of liquid viscosities and particle sizes, from sub-micron to millimetre-scale particles. This makes them suitable for diverse applications, such as emulsion stability studies, contaminant detection in pharmaceutical solutions, and quality control in food processing. Additionally, the systems can differentiate between air bubbles and solid particles, preventing false readings that could affect process decisions.

One of the major advantages of Canty’s liquid particle size analysers is their compliance with industry standards and regulatory requirements. Many of these instruments are designed to meet USP and ISO standards for particle size analysis in pharmaceutical and industrial applications. This ensures that companies using Canty analysers can produce products that meet strict quality control guidelines.

The analysers are equipped with software that allows users to visualise particle images in real-time, generate statistical reports, and conduct trend analysis. The software provides detailed insights into particle characteristics, such as aspect ratio, circularity, and transparency, which are critical parameters in many industrial processes. Additionally, the data collected by Canty analysers can be integrated with other process control systems, enabling seamless automation and data-driven decision-making.

Canty’s liquid particle size analysers are widely used in the oil and gas industry for monitoring the quality of drilling fluids, detecting contaminants in refined products, and analysing water quality in separation processes. In biotechnology and pharmaceuticals, they help ensure the consistency and purity of injectable drugs, suspensions, and other liquid formulations. The food and beverage industry benefits from Canty analysers by maintaining product consistency in dairy products, beverages, and emulsions.

Overall, Canty particle size analysers offer a cutting-edge, accurate, and efficient solution for liquid particle analysis. Their ability to provide real-time, high-resolution imaging, combined with advanced software analysis, makes them an invaluable tool across multiple industries, ensuring quality, efficiency, and compliance with stringent regulations.

Key Features:

- High-Resolution Imaging – Delivers clear and precise images for process monitoring.

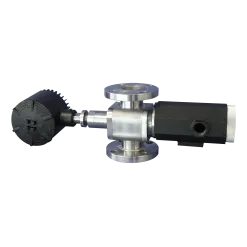

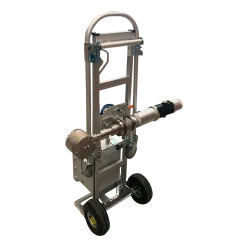

- Industrial-Grade Durability – Designed to withstand harsh environments, including high temperatures and pressure.

- Explosion Proof / Hazardous Area Certified – Available with ATEX, FM, and IECEx certifications for safe operation in hazardous locations.

- Integrated Lighting – Equipped with built-in LED or fiber optic lighting to enhance visibility in low-light conditions.

- Real-Time Process Monitoring – Provides continuous, live imaging for improved process control and efficiency.

- Zoom & Focus Control – Offers motorised or manual adjustments for optimal image clarity.

- Particle Size / Shape Analysis – Supports advanced imaging for applications such as liquid, powder, or emulsion analysis.

- Sanitary & CIP (Clean-in-Place) Designs – Suitable for food, beverage, pharmaceutical, and biotech industries.

- Versatile Mounting Options – Designed for various installation needs, including tank, pipe, and process vessel integration.

- Compatible with Image Analysis Software – Works seamlessly with CantyVision™ software for automated process control and data analysis.