Specifications

- Micronics ‘Ultraflo’ U1000MKII-FM Fixed Ultrasonic Clamp-On Flow Meter

- up to 6” pipe size – 125-180mm OD / 105-165mm ID

- Ultrasonic (time of flight) technology to measure flow rate / total flow from outside the pipe

- Includes volume pulse output (optional 4-20mA, Modbus OR M-Bus flow proportional outputs can be selected)

- Easy installation

- Cost effective alternative to traditional in-line meters

- Standalone instrument or as part of an integrated management system

- Temp range: -0°C to +85°C

- Flow range: 0.1m/s to 10m/s (0.3ft/s to 32ft/s)

- Accuracy: ±1% to ±3% (for 0.3m/s to 1ft/s)

- Rugged: IP54

- Backlit LCD

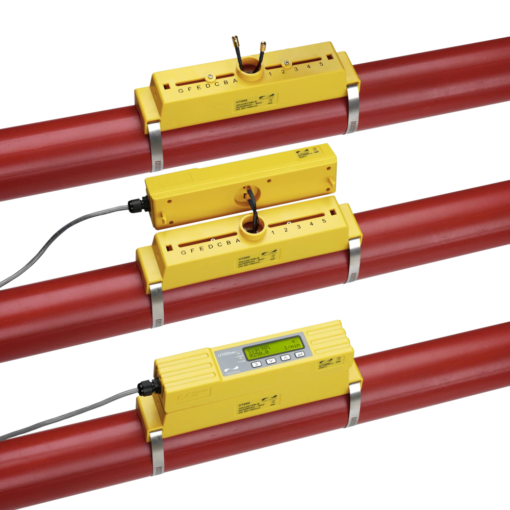

125-180mm Micronics U1000MKII-FM Fixed Ultrasonic Clamp-On Flow Meter

The standard meter with ‘pulse output’ pre-selected below AND the standard meter with ‘pulse + modbus output’ option selected, are both now in stock! Purchase online now.

The Micronics ‘Ultraflo’ U1000MKII-FM Fixed Ultrasonic Clamp-On Flow Meter (up to 6” pipe size – 125-180mm OD / 105-165mm ID) is suitable for water and glycol applications. This USM is a permanent/ fixed clamp-on metering solution that utilises ultrasonic technology to measure flow rate and total flow with a volume pulse output (standard) from outside the pipe. The U1000MKII-FM is a great value alternative to traditional inline heat / flow meter installation for use in industries such as energy management and building services. This clamp-on meter is easy to install as it has been factory configured and, because of this, requires minimal on-site programming and functions by simultaneously transmitting ultrasound between the clamp-on transducers in both directions. When ultrasound is emitted in the direction of flow the speed of the sound is accelerated; when it is emitted in the opposite direction the speed of the sound is decelerated. The time difference between ultrasound emissions is directly proportional to flow velocity. Using the flow velocity and the pipe’s cross-sectional area, the operator can calculate the volumetric flow.

Measurement Principle: Micronics meters use a cross-correlation transit time algorithm to provide accurate flow measurements. An ultrasonic beam of a given frequency is generated and applied to the transducer crystals. This transmission goes first from the downstream transducer to the upstream transducer as shown in the upper half of Figure 1 (below). The transmission is then made in the reverse direction, being sent from the upstream transducer to the downstream transducer as shown in the lower half of Figure 1. The speed at which the ultrasound is transmitted through the liquid is increased slightly by the velocity of the liquid through the pipe. The subsequent time difference T1-T2 is directly proportional to the liquid flow velocity.

Package contents

This fixed ultrasonic clamp-on flow meter includes adjustable transducer guide rail and all mounting hardware, banding and acoustic interface gel. A 24V DC external power supply and volume pulse output are standard unless other selections are made below: