Need help with your application? Contact us for expert advice on AMETEK Drexelbrook level instrumentation.

ABLE are AMETEK Drexelbrook’s Exclusive Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise across the full AMETEK Drexelbrook product range

- Our factory trained engineers offer after‑sales support, service and maintenance (contracts available)

- In‑depth AMETEK Drexelbrook product training, either in person or via video call

Further to the above, ABLE can offer customised solutions based on your individual requirements. Email us now at info@247able.com

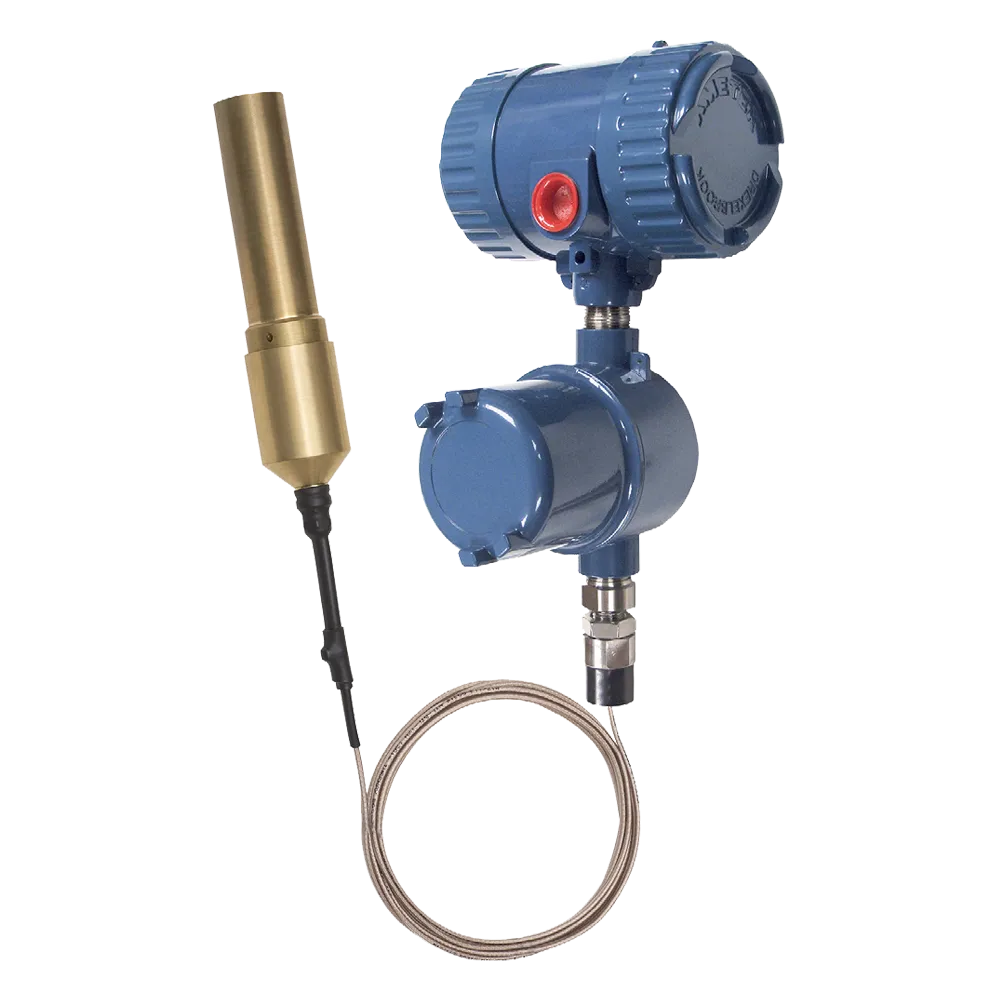

AMETEK Drexelbrook Floating Roof Tanks Spill Prevention Level Switch

SIL2 Certified RF Admittance Spill‑Preventer for Floating Roof Tanks

ABLE Instruments are AMETEK Drexelbrook’s Exclusive Representative for Sales and Service in the UK and Ireland, including the Floating Roof Tanks Spill Prevention Level Switch. The Floating Roof Tanks Spill Prevention Level Switch is engineered for overfill protection on internal and external floating roof storage tanks. Using RF admittance technology with Cote‑Shield™ coating immunity and flexible, field‑adjustable sensing probes up to 4.6 m in length, it continuously monitors liquid or roof contact. SIL2 certified and compliant with API 2350 spill-prevention standards, it features AutoVerify™ continuous diagnostics and Manual Certify™ test capability, allowing operators to fully test the system without removing the sensor from the tank.

Key Features:

- SIL2 certified: API 2350 compliant overfill switch designed for floating roof tanks

- Retractable flexible probe: Field-adjustable up to 4.6 m, supports remote maintenance

- No calibration needed: Auto-calibrating No‑Cal™ technology

- Cote‑Shield coating immunity: Ignores residue or buildup on sensing elements

- AutoVerify & Manual Certify: Continuous self-test and in-situ validation without removal

- Dual power options: Loop‑powered or line‑powered to suit installation preferences

- Dual compartment housing: Separates power and intrinsic safety circuits for robustness

- High sensitivity detection: Detects roof, rainwater or fuel contact within millimetres

Have a particular project in mind? We’d welcome a call on +44 (0) 1189 169 420

Operating via either loop‑power or line‑power, this system is suitable for high-integrity safety installations requiring reliable high‑level detection. The dual-compartment housing separates power wiring from intrinsically safe electronics, and the self-test circuitry automatically identifies faults, ensuring alerts even when coatings, residue or high media variability are present.

Ideal for oil terminals, tank farms and refining applications, this float-roof overfill switch prevents costly spills and protects personnel by detecting contact with roof hardware, fuel, or residual rainwater—detecting within millimetres of roof position changes.

Floating Roof Tanks Spill Prevention Specifications:

Technology | RF Admittance with Cote‑Shield coating immunity |

|---|---|

Certification | SIL2 (SIL3 redundant) to IEC61508; API 2350 compliant |

Probe Length | Field-adjustable from 0.3 to 4.6 m (1′ to 15′) |

Power Supply | Loop-powered or line-powered options available |

Output | DPDT relay switching; current output if loop‑powered |

Self‑Diagnostics | AutoVerify™ continuous test; Manual Certify™ feature |

Repeatability | Approx. ±2 mm detection accuracy |

Environmental Rating | IP66 / NEMA 4X with dual compartment design |

Approvals | FM, FMc, ATEX, IECEx (Class I Div 1 / Zone 0) |