Have a live application? Use our Flow Questionnaire and McCrometer Product Brochure to get started:

View ABLE Flow Questionnaire – Email back to info@247able.com

View McCrometer Product Brochure

ABLE are McCrometer’s Exclusive Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced McCrometer product training, either in-person or via video call.

Further to the above, ABLE can offer custom solutions based on your individual requirements. Email us now at info@247able.com

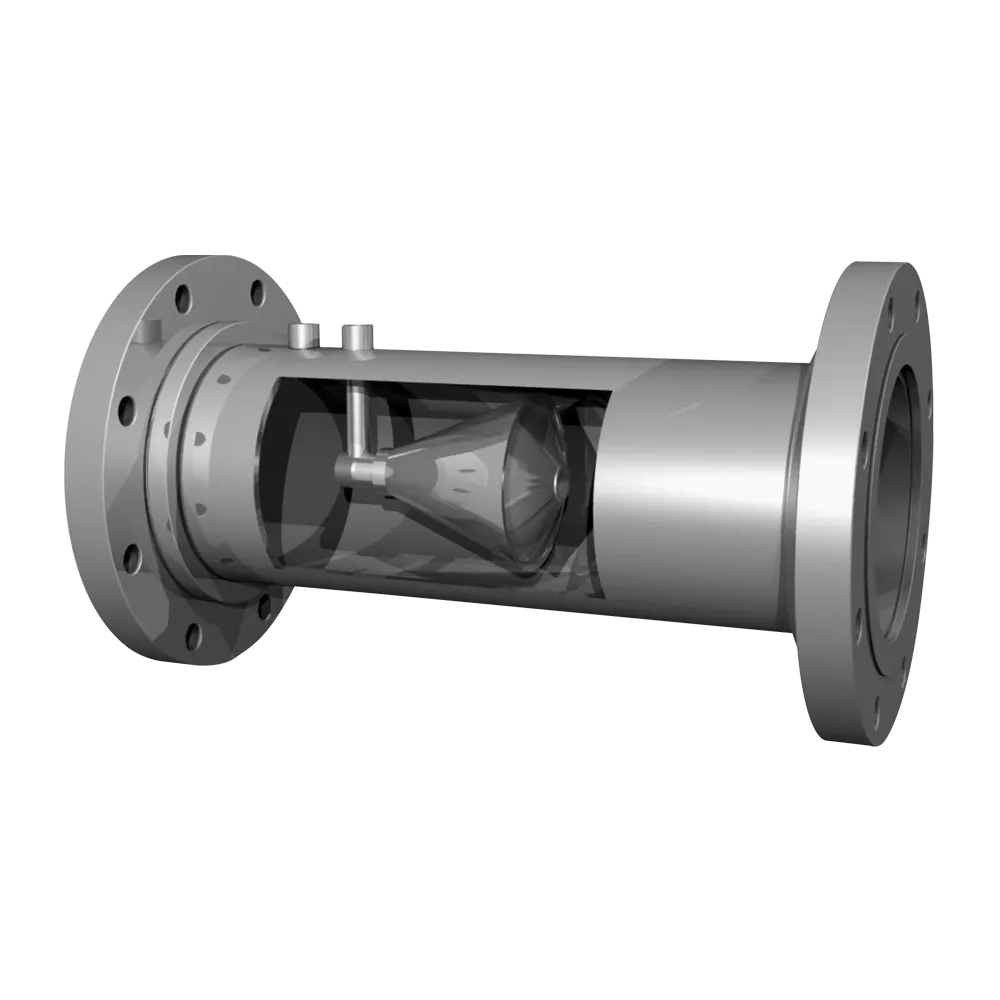

McCrometer V-Cone Differential Pressure Flow Meter

McCrometer Advanced Differential Pressure Measurement Technology for Liquid, Steam or Gas Measurement

ABLE Instruments are McCrometer’s Exclusive Representative for Sales and Service in the UK and Ireland, including the McCrometer V-Cone Differential Pressure Flow Meter. The V-Cone® flow meter is an advanced differential pressure measurement technology that offers superior performance in various industries, particularly in oil and gas. It has been tested in some of the harshest operating environments and with a wide range of fluid types, consistently outperforming traditional differential pressure devices and other major flow technologies. One of the key advantages of the V-Cone flow meter is its low installed cost. Unlike other flow meters that require long straight pipe runs or additional flow conditioning devices, the V-Cone’s design allows it to fit into tight spaces, making installation simpler and more cost-effective. When retrofitting existing systems, it often integrates seamlessly without requiring extensive modifications to the piping layout. Additionally, changes in upstream or downstream piping configurations do not impact its performance, ensuring long-term accuracy without the need for re-engineering.

Features:

- Accuracy: ±0.5% of flow rate.

- Repeatability: ±0.1% for consistent performance.

- Flow Range: Wide operating range with high turndown ratio.

- Flow Conditioning: Built-in design stabilises disturbed or swirling flows.

- Installation: Requires minimal straight pipe runs.

- Efficiency: Low head loss and low maintenance requirements.

- Calibration: No routine recalibration needed.

- Compliance: Suitable for use in ATEX-certified hazardous environments.

The V-Cone flow meter is also highly versatile, handling a broad range of flow conditions and fluid types. Acting as its own flow conditioner, it accurately measures disturbed or swirling flows, offering installation flexibility without sacrificing precision. Moreover, it is built to withstand abrasive, dirty, and particle-laden flows with minimal wear, making it ideal for challenging industrial environments. A distinguishing feature of the V-Cone flow meter is its ability to measure wet gas, steam, and condensate—an area where many other differential pressure technologies struggle. In side-by-side tests, the V-Cone was the only device that consistently provided accurate measurements for these difficult flow regimes.

With an accuracy of ±0.5% of rate and ±0.1% repeatability (depending on fluid type), the V-Cone flow meter maintains superior performance even under demanding conditions. It handles turndown ratios of 10:1 or greater without losing accuracy and boasts an exceptional lifespan of twenty-five years or more, making it a reliable and cost-effective solution for long-term flow measurement needs.

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

V-Cone System Additions:

DP Transmitters:

As an independent supplier, ABLE Instruments provides DP Transmitters tailored to customer specifications and preferred manufacturers. These transmitters are designed to interface with the V-Cone Meter, measuring the pressure difference generated by the primary element to determine flow rate. Depending on customer requirements, the transmitter can deliver either a linear or square root output. ABLE ensures high-quality solutions to meet specific application needs.

Manifolds:

A DP flow metering system requires a three-way or five-way manifold with primary isolation. The DP transmitter can be close-coupled or remote. For isolation, a double block and bleed valve (DB&B) is recommended to ensure safety and reliability in measurement.

Calibration:

ABLE Instruments offers calibration services for McCrometer V-Cone Flow Meters, which we recommend before they enter service. Calibration should be conducted under conditions closely resembling actual operation. Accuracy tests cover multiple flow points from minimum to maximum, assessing Flow Coefficient across the Reynolds Number range. This process characterizes the meter, reducing uncertainty. Traceable calibration ensures the meter meets specified tolerances. Verifying accuracy before deployment enhances measurement reliability.

McCrometer V-Cone Specifications:

Accuracy | ±0.5% of rate (certain fluids and Reynolds number applications require specific calibrations to achieve this value) |

|---|---|

Body material | Duplex 2205, 304, or 316 stainless steel, Hastelloy C-276, 254, SMO, carbon steels; Special materials on request |

Calibration | Calibrated for customer application |

Configurations | Precision flow tube and wafer-type |

Fitting Type | Flanged, threaded, hub or weld-end standard; Others on request |

Head Loss | Varies with beta ratio and DP |

Installation Requirement | Typically 0-3 diameters upstream and 0-1 diameters downstream of the cone are required, depending on fittings or valves in the adjacent pipeline |

Line size | 0.5 to 120″ or larger |

Pressure Range | Up to 20,000 psi (1,380 bar) |

Repeatability | ±0.1% |

Standard Beta Ratios | 0.45 to 0.80, special betas available |

Temperature Range | Up to 1,600 °F (870°C) |