Have a live application? Use our Mid-West Instrument Product Quick Selection Guide to configure the model and options for your requirement:

ABLE are Mid-West Instrument’s Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced Mid-West Instrument pressure gauge product training, either in-person or via video call.

Mid-West Model 105 Bellows Type Differential Pressure Gauge, 0.4 – 2.9 PSID

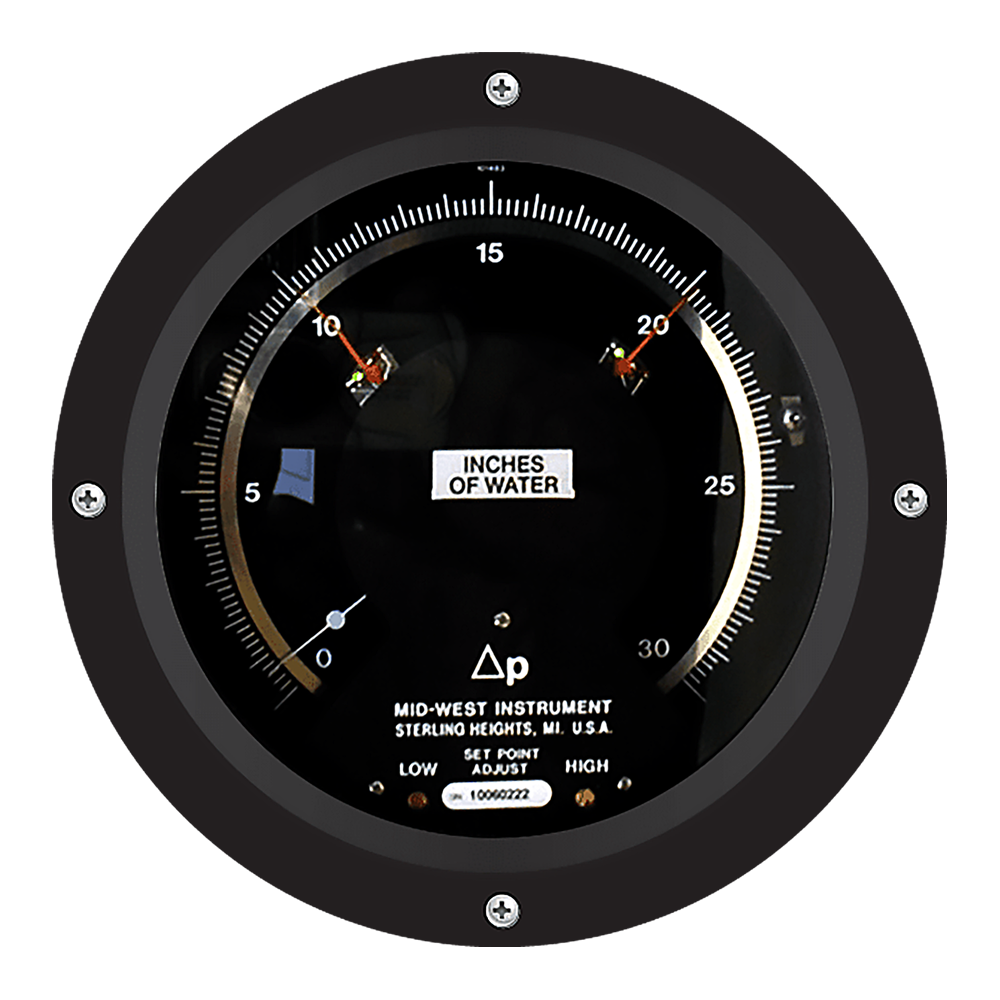

ABLE Instruments are Mid-West Instrument’s Official Representative for Sales and Service in the UK and Ireland, including the Model 105 Bellows Type Differential Pressure Gauge (0-0.4 to 0-2.9 PSID or equivalent). The Mid-West Model 105 Bellows ΔP Gauge stands out with its impressive ± 1/2% or ± 1% full-scale accuracy. This precision instrument leverages system pressure applied to an internal bellows and mechanical linkage assembly. As the pressure fluctuates, this assembly moves, triggering either an electrical signal or a gauge pointer movement. Key components of the Model 105 include a two-piece body, a bellows sensing element with an over-pressure assembly, a torque tube assembly, a range spring, and the gauge front assembly.

The Mid-West Model 105 boasts a rugged bellows sensing element, a glass-reinforced thermoplastic dial case, and a weather / corrosion-resistant gauge front. Its 270° dial arc and shatter-resistant lens enhance readability and durability. Available dial sizes are 4-1/2” and 6”, with scale ranges from 0-10” H2O to 0-79.9” H2O, and it supports multiple dial scales including bar, mbar, kPa, and more. The gauge operates under pressures up to 6000 PSIG and temperatures ranging from -40°F to +200°F. With robust materials like aluminium, carbon steel, stainless steel, and brass, and versatile applications in tank monitoring, water treatment, and hydraulic systems, the Model 105 gauge is a reliable choice for precise differential pressure measurement.

Features:

- Durable bellows sensing element

- Panel-mountable dial case made of glass-reinforced thermoplastic

- Front of gauge is resistant to weather and corrosion

- 270° dial arc

- Shatter-resistant lens

- Over-range protection for both High over Low and Low over High

- Locked-Logic switch options available

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

The body halves of the Model 105 bellows type gauge ensure effective pressure containment, clamping the sensing element and over-pressure assembly between them to segregate high and low side pressures. The high side body half supports the torque tube and gauge front assemblies. A unique feature of this differential pressure gauge is its bidirectional relief valve, offering over-pressure protection in both directions. When the high side is over-pressured, a mechanical stop opens the valve as the sensing element reaches its maximum deflection. Conversely, if the low side is over-pressured, the spring-loaded valve opens when differential pressure surpasses its limit, equalising pressure to safeguard the unit.

What is the ‘Locked-Logic’ switch option? The “Locked Logic” alarm control is a solid-state optical-electronic control option for Mid-West Models 105 differential pressure gauges, designed to maintain gauge accuracy. The standard unit operates on 8 to 28 VDC power, with optional inputs of 115 VAC or 220/240 VAC (50-60 hertz). The output interface includes one or two isolated SPDT or DPDT relay contacts, with adjustable set pointers within 5% of full scale. An adjustable deadband option allows the right set pointer to trigger the upper limit and the left to trigger the lower limit. The unit features weather-proof NEMA 4X or NEMA 7 enclosures and is suitable for hazardous locations, including Class I Division I and Class II Division I groups.

Model 105 Specifications:

For Full Specifications | |

|---|---|

Dial Sizes | 4-1/2” and 6” Diameters |

Dial Scale Ranges | 0-10” H2O to 0-79.9” H2O (0-0.4 PSID to 0-2.9 PSID) |

Differential Full Scale Ascending Accuracy | ±1/2% (ASME B40.1 Grade 2A) ±1% (ASME B40.1 Grade 1A) |

Available Dial Scales | Bar, Mbar, kPa, Kg/Cm2, Dual Scale and Square Root for Flow Indication etc. |

Working Pressure | Up to 6000 PSIG (400 Bar) |

Operating Temperature | -40°F to +200°F (-40°C to +93°C) |

Material (Body) | Aluminium, Carbon Steel, 316/316L Stainless Steel and Brass (Wetted Part) |

Internal Wetted Parts | 316 Stainless Steel |

Process Connection | Dual Top and Bottom |

O-rings Material | Buna-N, Viton, and Ethylene Propylene |