Have a live application? Use our Mid-West Instrument Product Quick Selection Guide to configure the model and options for your requirement:

ABLE are Mid-West Instrument’s Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced Mid-West Instrument pressure gauge product training, either in-person or via video call.

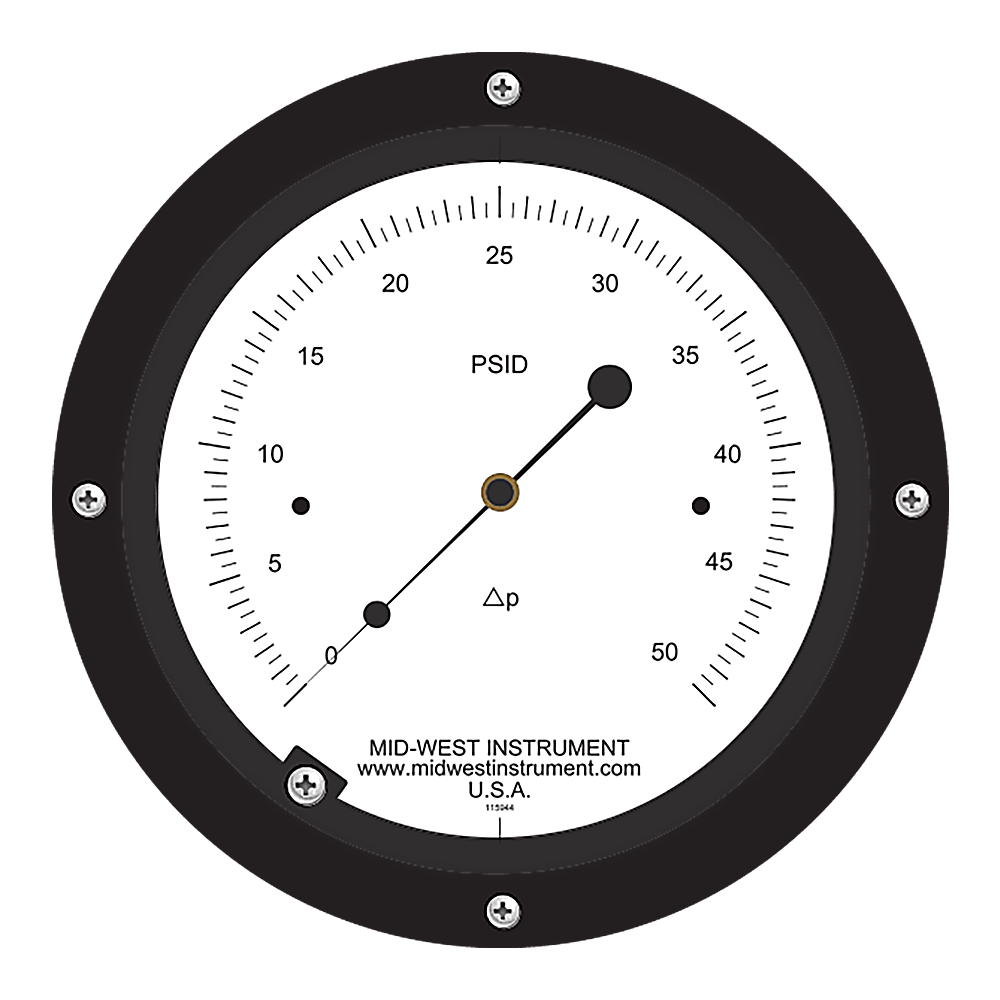

Mid-West Model 109 Bourdon Type Differential Pressure Gauge, 15 – 6,000 PSID

ABLE Instruments are Mid-West Instrument’s Official Representative for Sales and Service in the UK and Ireland, including the Model 109 Bourdon Type Differential Pressure Gauge (0-15 to 0-6,000 PSID or equivalent). The Model 109 Bourdon Tube ΔP Gauge delivers precise differential pressure measurements with an accuracy of ± 1/2% or ± 1% full scale. This gauge operates by applying system pressure to the inside of a slightly flattened, arc-shaped tube. As pressure increases, the tube attempts to return to its original round shape, causing it to straighten. One end of the tube is fixed, so the tip moves in an arc, reflecting the change in pressure. The Model 109 uses a high-quality Bourdon Tube Assembly encapsulated in a high-pressure chamber, which has two connections: one to the inside of the Bourdon Tube and one to the pressure chamber. This setup allows the gauge to measure the difference between the pressures inside the tube and the chamber.

The Mid-West Model 109 is designed with a rugged Bourdon Tube sensing element, a glass-reinforced thermoplastic dial case, and a weather- and corrosion-resistant gauge front. Its 270° dial arc and shatter-resistant lens provide clear and durable readings. Available dial sizes are 4-1/2” and 6”, with scale ranges from 0-15 PSID to 0-6,000 PSID. It supports various units, including bar, mbar, and kPa. The gauge operates under pressures up to 6000 PSIG and temperatures from -40°F to +200°F. Constructed from materials like aluminium, carbon steel, stainless steel, and brass, the Mid-West Instrument Model 109 differential pressure gauge is ideal for applications such as pump performance testing, hydraulic filter monitoring, and heat exchanger pressure drop monitoring.

Features:

- Durable bourdon tube sensing element

- Panel-mountable dial case made of glass-reinforced thermoplastic

- Front of gauge is resistant to weather and corrosion

- 270° dial arc

- Shatter-resistant lens

- Over-range protection for both High over Low and Low over High

- Locked-Logic switch options available

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

The Model 109 features a bi-directional relief valve that protects the Bourdon Tube Assembly against over-range pressure in both directions. The pressure gauge’s output shaft is magnetically coupled through the solid wall of the pressure chamber to a sensitive jewelled pointer shaft in the dial housing, ensuring precise transmission of movement to the pointer for accurate readings. Notably, the use of diaphragm seals is not recommended for this model, as it voids the warranty.

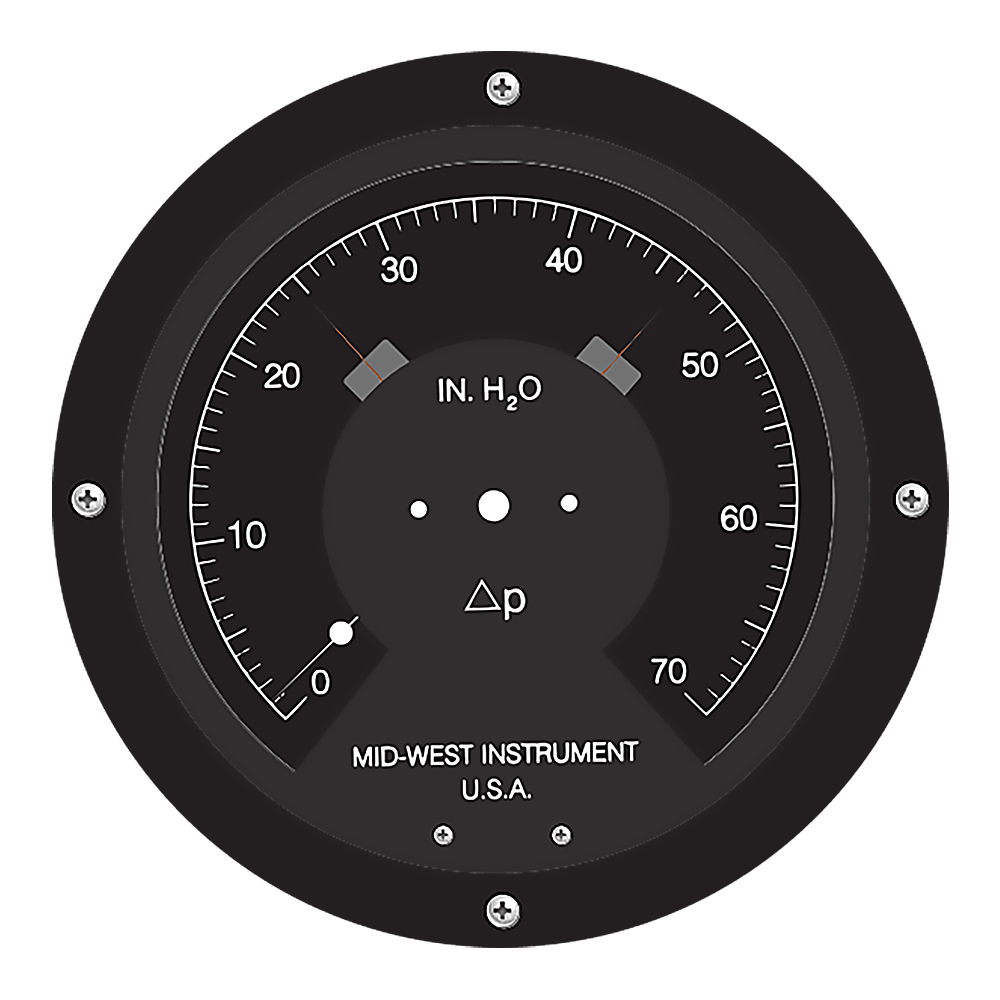

What is the ‘Locked-Logic’ switch option? The “Locked Logic” alarm control is a solid-state optical-electronic control option for Mid-West Model 109 differential pressure gauges, designed to maintain gauge accuracy. The standard unit operates on 8 to 28 VDC power, with optional inputs of 115 VAC or 220/240 VAC (50-60 hertz). The output interface includes one or two isolated SPDT or DPDT relay contacts, with adjustable set pointers within 5% of full scale. An adjustable deadband option allows the right set pointer to trigger the upper limit and the left to trigger the lower limit. The unit features weather-proof NEMA 4X or NEMA 7 enclosures and is suitable for hazardous locations, including Class I Division I and Class II Division I groups.

Model 109 Specifications:

For Full Specifications | |

|---|---|

Dial Sizes | 4-1/2” and 6” Diameters |

Dial Scale Ranges | 0-15 PSID to 0-6,000 PSID |

Differential Full Scale Ascending Accuracy | ±1/2% (ASME B40.1 Grade 2A) ±1% (ASME B40.1 Grade 1A) |

Available Dial Scales | Bar, Mbar, kPa, Kg/Cm2, Dual Scale and Square Root for Flow Indication etc. |

Working Pressure | Up to 6000 PSIG (400 Bar) |

Operating Temperature | -40°F to +200°F (-40°C to +93°C) |

Material (Body) | Aluminium, Carbon Steel, 316/316L Stainless Steel and Brass (Wetted Part) |

Internal Wetted Parts | 316 Stainless Steel |

Process Connection | Back |

O-rings Material | Buna-N, Viton, Neoprene, and Ethylene Propylene |