Have a live application? Use our Mid-West Instrument Product Quick Selection Guide to configure the model and options for your requirement:

ABLE are Mid-West Instrument’s Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced Mid-West Instrument pressure gauge product training, either in-person or via video call.

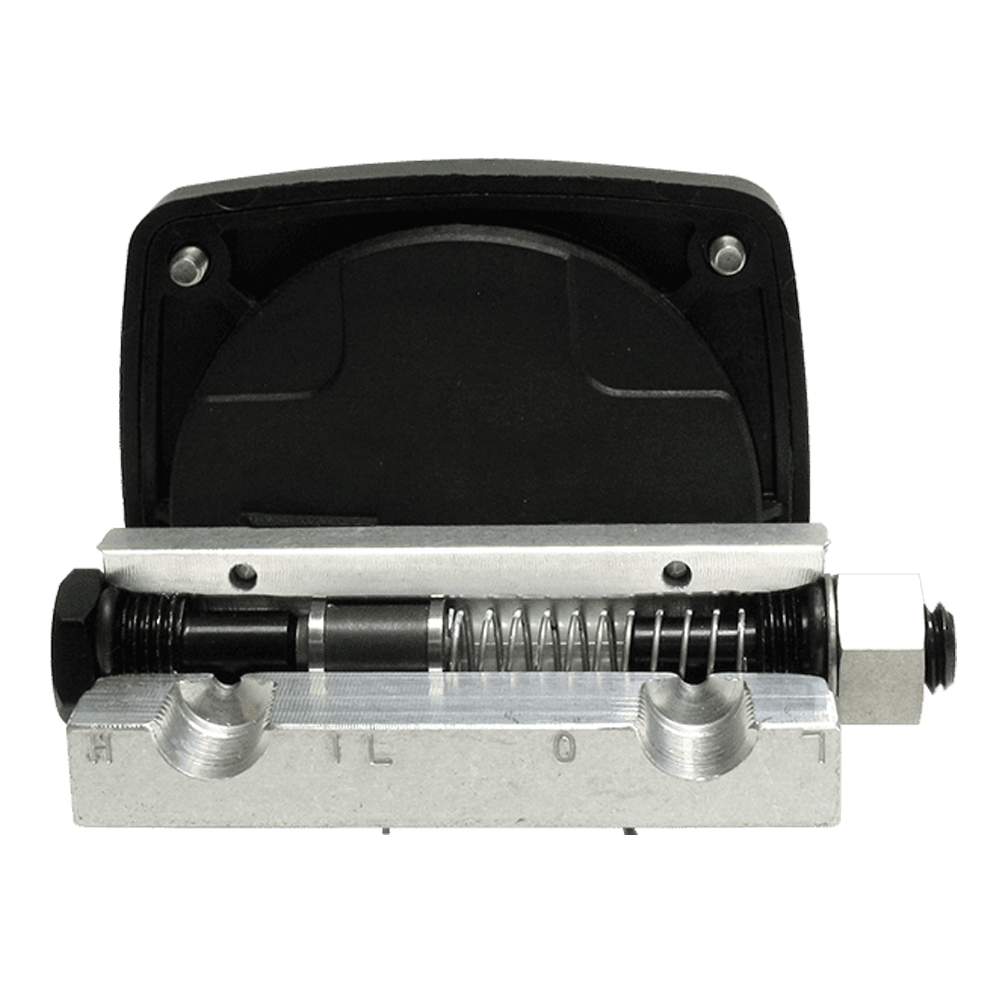

Mid-West Model 120 Piston Type Differential Pressure Gauge, 5 – 110 PSID

ABLE Instruments are Mid-West Instrument’s Official Representative for Sales and Service in the UK and Ireland, including the Model 120 Piston Type Differential Pressure Gauge (0-5 to 0-110 PSID or equivalent). Mid-West Model 120 piston-type gauges are specifically designed for liquid applications, offering precise and reliable differential pressure measurements. The DP gauge operates by sensing differential pressure through the movement of a finely ground floating piston/magnet within a precision bore, calibrated against a spring. When there is a variation in pressure on either side of the piston/magnet, the magnet moves proportionally to the change in differential pressure. This movement is tracked by a rotary pointer magnet situated outside the pressure housing, which follows the internal magnet’s motion and displays the differential pressure on the dial. Notably, piston-type Model 120 DP gauges allow a slight bypass as the fluid transitions from the high to the low-pressure port.

These Model 120 gauges boast a differential pressure range of 0-5 PSID to 0-110 PSID (0-0.35 to 0-7.0 bar) and come in various equivalent ranges and scales, ensuring flexibility for different applications. The Model 120 maintains an accuracy of ±2% and operates effectively within a temperature range of -40ºF to +200ºF (-40ºC to +93ºC). Dial sizes available include the standard 2-1/2″ round, with optional 3-1/2″ and 4-1/2″ rounds. It can handle working pressures up to 6000 PSIG, making it suitable for high-pressure environments.

Features:

- Simple and durable piston-type design sensing element

- Panel-mountable dial case made from glass-reinforced thermoplastic.

- Optional anodised aluminium dial case available—contact ABLE for details.

- Resistant to weather and corrosion.

- Shatter-resistant lens.

- Over-range protection for high-over-low and low-over-high scenarios.

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

Constructed with durable materials such as aluminium, 316/316L stainless steel, aluminium bronze, and Monel, the Mid-West Model 120 ensures longevity and resilience. Internal components are primarily made from 316 stainless steel, with Monel options available for specific needs. The Mid-West gauge also offers various switch options, including SPDT and SPST configurations, and can be housed in weather-resistant, NEMA 4X, or NEMA 7 electrical enclosures.

What are the electrical switch specifications? The Mid-West Instrument Model 120 switches offer mechanical adjustability, allowing customers to set the switch within a specified adjustment span of the instrument’s range. This model can be configured with either one or two switches, with each switch being independently adjustable in dual-switch units. Mid-West can also preset switch set points upon customer request. For comprehensive switch specifications, refer to the Installation Manual. These switches operate without requiring power and can include one or two independently adjustable switches. There are several switch output options available, including:

- SPDT 3W, 0.25 Amp, 125 VAC/VDC

- SPST 60W, 3.0 Amp, 240 VAC/VDC (Normally Open)

- SPDT 60W, 3.0 Amp, 240 VAC/VDC (Normally Closed)

- SPST 60W, 3.0 Amp, 240 VAC/VDC (1 Normally Open, 1 Normally Closed)

- SPDT 60W, 1.0 Amp, 240 VAC/VDC

The non-hazardous switches are CE marked in compliance with Low Voltage and RoHS Directives. The electrical enclosures are weather-resistant, meeting NEMA 4X standards, and there is an option for a DIN connector. For hazardous locations, there are options suitable for Class I Division 1, Class II Division 1, Class I Division 2, and Class II Division 2. The complete assembly is third-party certified.

Model 120 Specifications:

For Full Specifications | |

|---|---|

Dial Sizes | 2-1/2”, 3-1/2”, 4-1/2” and 6” Diameters (Uni-Directional & Bi-Directional) |

Dial Scale Ranges | 0-5 PSID to 0-110 PSID (0-0.35 bar to 0-7.0 bar) |

Full Scale Ascending Accuracy | ±3/2/3% (ASME B40.1 Grade B) |

Working Pressure | Up to 6000 PSIG (400 Bar) |

Operating Temperature | -40°F to +200°F (-40°C to +93°C) |

Material (Body) | Aluminium, 316/316L Stainless Steel, Alum/Bronze and Monel (Wetted Part) |

Internal Wetted Parts | 316 Stainless Steel, Ceramic Magnet, Alum/Bronze, Monel (Dependent on model chosen) |

Process Connection | Multiple instrument process connection size and locations available |

O-rings Material | Buna-N, Viton, Neoprene, Teflon, Ethylene Propylene (Perfluoroelastomer optional) |