Have a live application? Use our Mid-West Instrument Product Quick Selection Guide to configure the model and options for your requirement:

ABLE are Mid-West Instrument’s Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced Mid-West Instrument pressure gauge product training, either in-person or via video call.

Mid-West Model 140 Diaphragm Type Differential Pressure Gauge, 2 – 100 PSID

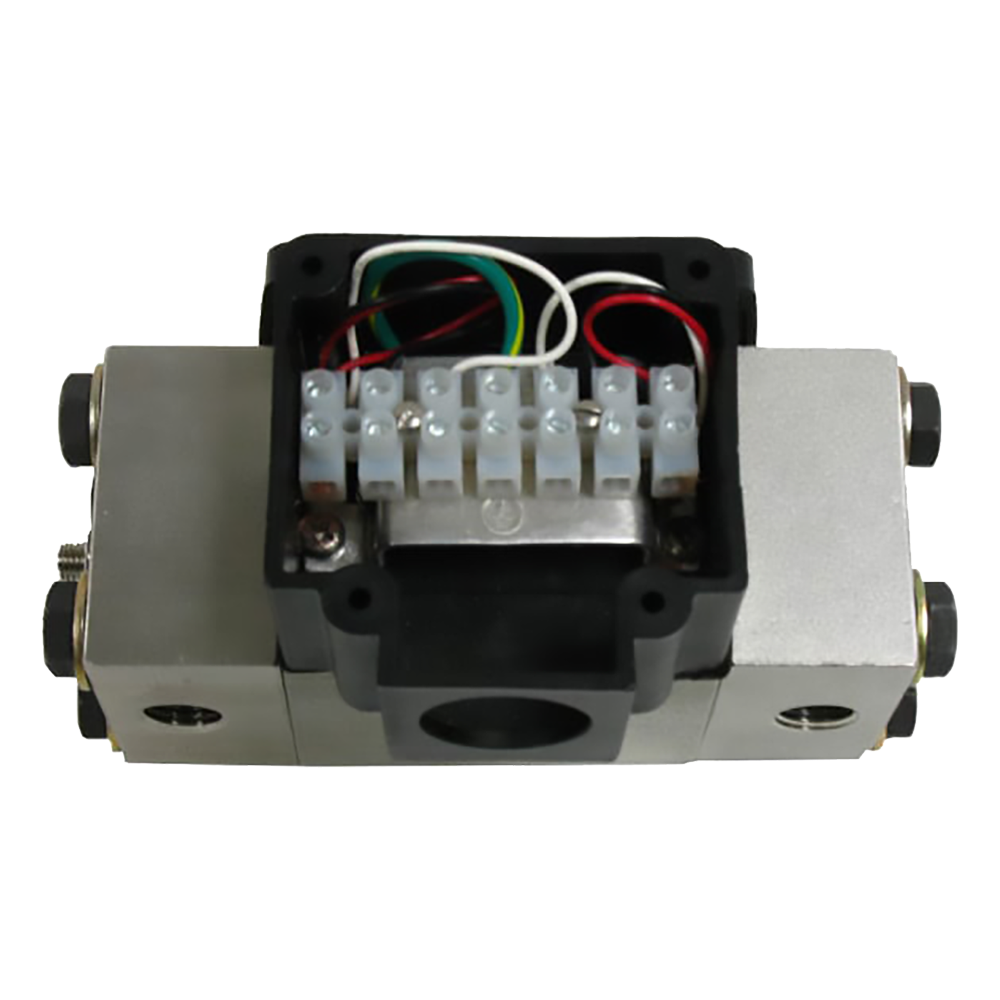

ABLE Instruments are Mid-West Instrument’s Official Representative for Sales and Service in the UK and Ireland, including the Model 140 Diaphragm Type Differential Pressure Gauge (0-2 to 0-100 PSID or equivalent). The Model 140 from Mid-West Instrument is a highly adaptable convoluted diaphragm type gauge designed to meet the rigorous demands of differential pressure applications. It features a terminal strip interface to simplify the electrical installation of switches or transmitters, and it offers the option to integrate a 4-20 mA transmitter for continuous monitoring needs. The Model 140 supports multiple switch configurations, including those suitable for hazardous locations, making it an accurate and versatile choice for a wide range of industrial environments.

This differential pressure gauge/switch boasts full-scale accuracies of ±5% for ranges from 0-50” H2O to 399” H2O, and ±3/2/3% for ranges from 0-15 PSID to 0-100 PSID, ensuring precise measurements under varying conditions. Its rugged design includes a glass-reinforced thermoplastic dial case, which is panel mountable, with an optional anodized aluminium case for enhanced durability. The Model 140 is built to withstand weather and corrosion, featuring a shatter-resistant lens and over-range protection for both high-over-low and low-over-high conditions. It comes with a five-year warranty, reflecting its reliability and durability.

Available in dial sizes of 2-1/2”, 3-1/2”, 4-1/2”, and 6” diameters, the Model 140 supports a wide range of dial scales including Bar, Mbar, kPa, Kg/Cm2, and dual scales. It can handle working pressures up to 3000 PSIG (200 Bar) and operates in temperatures ranging from -40°F to +200°F (-40°C to +93°C). The gauge is protected to NEMA 4X/IP65 standards, ensuring resistance to environmental factors.

Features:

- Durable convoluted diaphragm design

- Panel-mountable dial case made of glass-reinforced thermoplastic (optional anodized aluminium dial case available; contact ABLE for more information)

- Resistant to weather and corrosion

- Shatter-resistant lens

- Over-range protection for both high-over-low and low-over-high scenarios

- Terminal strip switch and transmitter options available

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

The construction materials include aluminium, brass, 316/316L stainless steel, aluminium/bronze, and Monel for the wetted parts, ensuring compatibility with various industrial fluids. Internal wetted parts consist of 316 stainless steel, ceramic magnets, Teflon guide bushings, and Monel, depending on the model. The Model 140 offers flexibility with multiple process connection sizes and locations, and elastomer options for the O-rings and diaphragm materials, such as Buna-N, Viton, silicone, neoprene, and ethylene propylene.

Ideal for applications like filter and strainer monitoring, compressed air, hydraulics, refrigerants, pump performance testing, heat exchanger pressure drop monitoring, water treatment, tank level monitoring, and flow monitoring and balancing, the Model 140 is designed to deliver reliable performance across various industries.

What are the electrical switch specifications? Mid-West Instrument switches are designed with mechanical adjustability, allowing customers to set the switch within a specific adjustment range of the instrument. If needed, Mid-West can also preset switch set points according to customer requests. All switches comply with the EU Low Voltage and RoHS Directives and are CE marked. For hazardous location and transmitter configurations, a ½” FNPT conduit interface is provided.

The Mid-West Instrument Model 140 is a differential pressure transmitter, available in both indicating and non-indicating versions. It is a 2-wire loop-powered microprocessor-based transmitter that outputs a 4-20 mA signal. The transmitter utilizes a magnetic angle sensor and electronics to detect the angle of a magnet that moves linearly within the bore, relative to the sensor. Each transmitter undergoes an individual 11-point calibration linearization process to ensure precision. Note that transmitter options are not CE marked.

These switches require no power to operate and can be equipped with one or two independently adjustable switches. The 4-20 mA transmitter operates on 8-28 VDC loop power with an accuracy of 2% (20%-100% of scale, ascending). Available switch output options include:

- SPDT 3W, 0.25 Amp, 125 VAC/VDC

- SPST 25W, 0.5 Amp, 230 VAC/VDC (Normally Open)

The switches and transmitters are housed in weather-resistant, NEMA 4X/IP66 electrical enclosures. Non-hazardous switches are CE marked in accordance with Low Voltage and RoHS Directives.

For hazardous locations, the switches can be configured for Class I Division I (Groups C & D) and Class II Division I (Groups E, F & G), though these configurations are not CE marked. Additionally, options for Class I Division II (Groups A, B, C & D) and Class II Division II (Groups F & G) are available.

Model 140 Specifications:

For Full Specifications | |

|---|---|

Dial Sizes | 2-1/2”, 3-1/2”, 4-1/2” and 6” Diameters |

Full Scale Ascending Accuracy | 50” H2O to 399” H2O ±5% (ASME B40.1 Grade D) 15 PSID to 100 PSID ±3/2/3% (ASME B40.1 Grade B) |

Dial Scale Ranges | 0-50” H2O to 0-100 PSID (0-125 mbar to 0-7.0 bar) |

Available Dial Scales | Bar, Mbar, kPa, Kg/Cm2, Dual Scale etc. |

Working Pressure | 3000 PSIG (200 Bar) |

Operating Temperature | -40°F to +200°F (-40°C to +93°C) |

Weather Protection | NEMA 4X/IP65 |

Material (Body) | Aluminium, Brass, 316/316L Stainless Steel, Aluminium/Bronze & Monel(Wetted Part) |

Internal Wetted Parts | 316 Stainless Steel, Ceramic Magnet, Teflon Guide Bushings and Monel (Dependent on model chosen) |

Process Connections | Multiple instrument process connection size and locations available |

O-rings Material | Elastomers (O-rings and Diaphragm Materials) Buna-N, Viton, Silicone, Neoprene, Ethylene Propylene |