Have a live application? Use our Mid-West Instrument Product Quick Selection Guide to configure the model and options for your requirement:

ABLE are Mid-West Instrument’s Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Application expertise

- Our factory trained engineers offer after sales support, service and maintenance (contracts available)

- Offer advanced Mid-West Instrument pressure gauge product training, either in-person or via video call.

Mid-West Model 240 Diaphragm Type Flame Proof Differential Pressure Gauge, 0.7 – 100 PSID

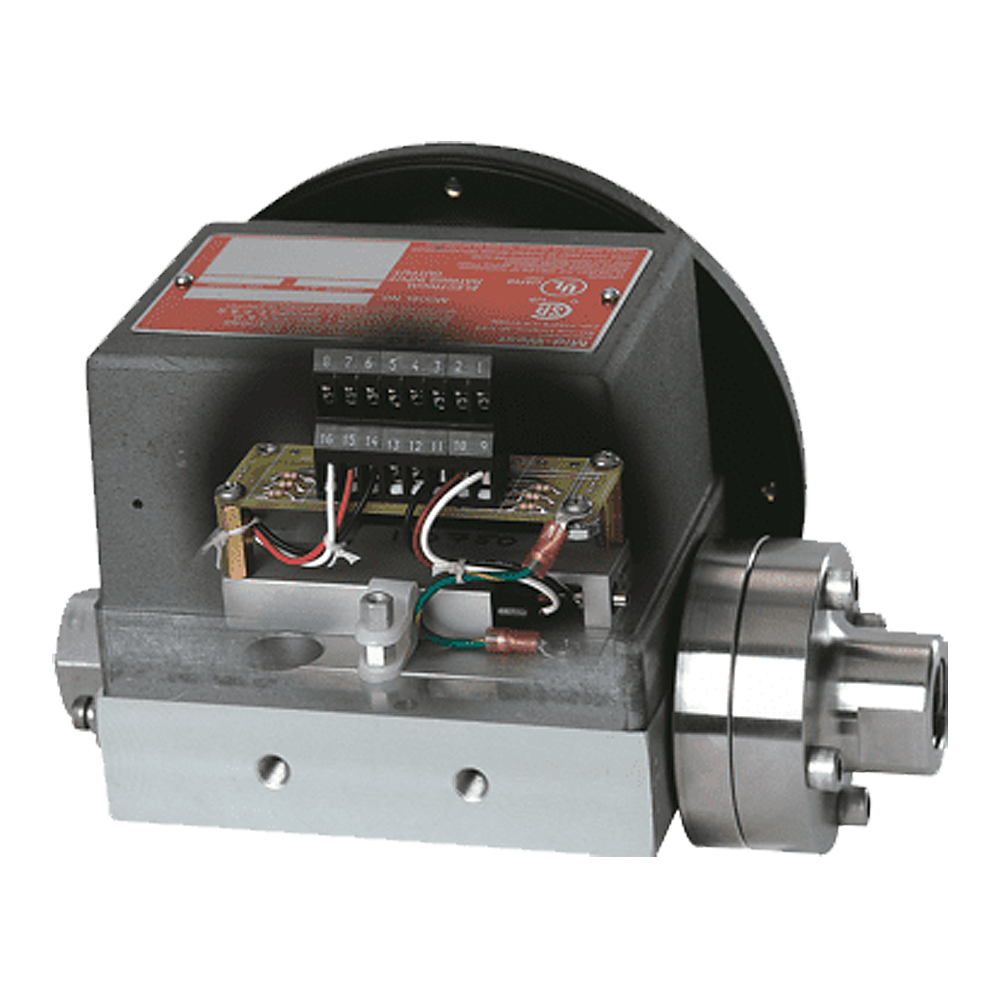

ABLE Instruments are Mid-West Instrument’s Official Representative for Sales and Service in the UK and Ireland, including the Model 240 Diaphragm Type Flame Proof Differential Pressure Gauge (0-0.7 to 0-100 PSID or equivalent). The Model 240 is a rugged, compact diaphragm-type differential pressure gauge specifically designed for hazardous locations. It is fully certified for use in Class I, Division 1, Groups B, C, & D, Class II, Division 1 Groups E, F & G, and Class I Division 2, Groups E, F, & G environments. The gauge also meets Ex d IIB + H2 and Ex tb IIIC IP6X standards, ensuring it is suitable for both dust and gas hazardous areas. With third-party certifications from CSA, UL, ATEX, IEC Ex, and KOSHA Ex IIB + H2, along with compliance with the EU RoHS2 directive, the Model 240 offers a high level of safety and reliability.

Constructed with a glass-reinforced thermoplastic dial case, with an optional anodized aluminium dial case available, the Model 240 is both weather and corrosion-resistant. Its shatter-resistant lens and over-range protection capabilities for high over low and low over high pressure make it a durable option for challenging environments. The gauge is equipped with a field-accessible terminal strip and offers versatile output options, including a 4-20 mA transmitter, switch, and relay outputs, with switch outputs that require no power to operate.

The Model 240 features a 4-1/2” dial size and provides differential full-scale ascending accuracy of ±3/2/3% according to ASME B40.1 Grade B standards. It supports dial scale ranges from 0-20” H2O to 0-100 PSID, accommodating various pressure measurement needs. The gauge is built to handle working pressures up to 1,500 PSI (100 Bar) and operates across a wide temperature range, with specific limits depending on the selected output option.

Features:

- ATEX approved – Ex d IIB + H2 and Ex tb IIIC IP6X

- Rugged and compact Diaphragm Type design

- Glass reinforced thermoplastic dial case (Anodised aluminium dial case option available. Contact ABLE for more information)

- Weather / Corrosion resistant

- Shatter resistant lens

- Over-range protection, High over Low and Low over High

- Terminal strip switch / transmitter options

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at info@247able.com

Manufactured using high-quality materials, including aluminium and 316 stainless steel for the wetted pressure-containing body assembly, and internal parts like a ceramic magnet, the Model 240 is engineered for longevity. It offers flexibility with available elastomers such as Buna-N, Viton, and Ethylene Propylene. The gauge is designed with ¼-20 mounting holes in the back of the gauge body and is available with ¼” FNPT or ½” FNPT end connections.

Ideal for monitoring differential pressure in filters, strainers, separators, valves, and pumps, the Model 240 is a reliable and versatile solution for maintaining system performance in critical applications.

What are the electrical switch specifications?

Mid-West Instrument Hazardous Location switches come equipped with a field-wireable terminal strip, eliminating the need for a costly explosion-proof junction box near the switch. These switches are easily adjustable, allowing customers to set them within a specified adjustment range of the instrument. All configurations feature a ½” FNPT conduit interface. Mid-West can also pre-set switch set points upon customer request. For ATEX options, switches are CE marked in accordance with the EU ATEX and RoHS Directives.

The Mid-West Instrument 240 differential pressure transmitter, available in both indicating and non-indicating versions, is a two-wire, loop-powered, microprocessor-based 4-20 mA transmitter. It utilises a magnetic angle sensor and electronics to detect the angle (relative to the transmitter sensor) of a magnet that moves linearly in the bore. Each transmitter undergoes individual calibration to the gauge using an 11-point calibration linearisation method.

- No Power required to operate switches ; Relay Option Requires Power

- 1-2 Independent adjustable Switches

Available Electrical Output options include:

- SPDT 3W, 0.25 Amp, 125 VAC/VDC

- SPST 60W, 3.0 Amp, 240 VAC/VDC (Normally Open)

- SPDT 60W, 1.0 Amp, 240 VAC/VDC

- DPDT Relay, 10.0 Amp @ 30 VDC 120/240 VAC

- 4-20 mA Transmitter (8-28 VDC Loop Power) 2% Accuracy (20%-100% of scale, Ascending)

Electrical Enclosures Weather-Resistant:

- CSA & US – NEMA 4X Optional

- ATEX IECEx – IP65

Model 240 Specifications:

For Full Specifications | |

|---|---|

Dial Sizes | 4-1/2” |

Full Scale Ascending Accuracy | ±3/2/3% (ASME B40.1 Grade B) |

Dial Scale Ranges | 0-20” H2O to 0-100 PSID (0-50 mbar to 0-7.0 bar) |

Dial Scales | Bar, Mbar, kPa, Kg/Cm2, Dual Scale etc. |

Working Pressure | 1,500 PSI (100 Bar) |

Operating Temperature | -40°F (-40°C) to +185°F to (+85°C) -40°F (-40°C) to +160°F (+70°C)–For output option R (Relay Output) -20°F (-30°C) to +150°F (+65°C)–For output option 4-20 mA Transmitter |

Mounting Holes | ¼-20 Mounting Holes in back of gauge body |

Material (Body) | Aluminium and 316 Stainless Steel Wetted Pressure containing body assembly |

Internal Wetted Parts | 316 Stainless Steel, Ceramic Magnet |

Process Connections | ¼” FNPT or ½” FNPT End connections only |

Elastomers | (O-ring and Diaphragm materials) Buna-N, Viton,and Ethylene Propylene |