Have a live application? Use our Flow Questionnaire and Rheonik Product Brochure to get started:

View ABLE Flow Questionnaire – Email back to [email protected]

ABLE are Rheonik’s Exclusive Representative for Sales and Service in the UK and Ireland and can assist you and your customers in the following areas:

- Assistance in meter sizing

- Offer after sales support, service and re-calibration utilising our in-house expertise

- Offer Coriolis Mass Flow Meter product training from our state-of-the-art training rig either in-person or via video call.

Further to the above, ABLE can offer custom solutions based on your individual requirements. Email us now at [email protected]

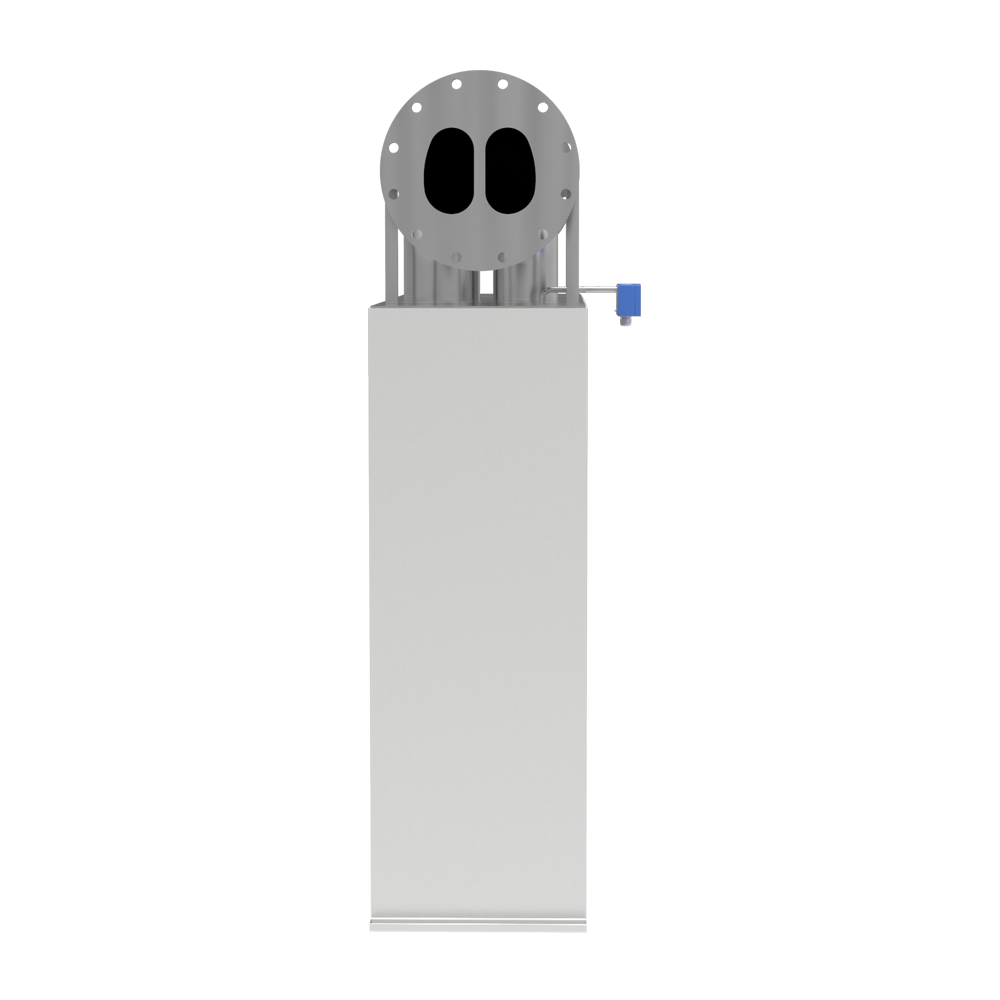

Rheonik RHM 160 Large Coriolis Mass Flow Meter < 30000 kg/min

ABLE Instruments are Rheonik’s Exclusive Representative for Sales and Service in the UK and Ireland, including the RHM 160 Large Size Coriolis Mass Flow Meter. The RHM 160 stands as the quintessential choice for cargo and pipeline applications, redefining precision and efficiency. Its remarkable combination of high accuracy and low pressure drop makes it the ultimate solution for swiftly transferring substantial fluid quantities with unwavering confidence.

This meter boasts an impressive flow range, spanning from 250 kg/min to 30,000 kg/min, catering to the demands of industries requiring the rapid transfer of large fluid volumes. It is the go-to choice for applications where speed, accuracy, and capacity matter most.

Even in high-pressure scenarios, the Rheonik RHM 160 excels, with the capability to withstand pressures of up to 52 bar (754 psi). This robustness ensures that it can operate seamlessly in environments where the fluid transfer process demands precision and reliability.

The meter’s ability to function across extreme temperature ranges is equally remarkable. Operating effectively in conditions ranging from a frigid -196°C (-321°F) to a scorching +120°C (248°F), it maintains its accuracy and reliability, regardless of the environmental conditions.

Features:

- Range: 250 kg/min up to 30000 kg/min

- Pressure: up to 52 bar (754 psi)

- Temperature: -196°C (-321°F) up to +120°C (248°F)

- Accuracy: 0.1 % of rate

- Materials: SS 316L / SS 316Ti, Alloy C22 – 2.4602

- Process Connection: 12″ up to 12″

- Suitable for fiscal / custody transfer applications

- Available in all exotic materials

Precision is at the core of the Rheonik RHM 160 Mass Flow Sensor, with an accuracy rate of 0.1% of the rate, ensuring that the data it provides is consistently dependable. This level of accuracy is indispensable in cargo and pipeline applications where even the slightest deviation can result in significant consequences. Constructed with a selection of robust materials, including SS 316L, SS 316Ti, and Alloy C22 – 2.4602, the RHM 160 is compatible with a wide range of fluids and stands strong against corrosion. The meter’s adaptability is further heightened by its process connections, ranging from 12″ to 12″, allowing for seamless integration into existing systems and configurations.

In summary, the RHM 160 Coriolis Mass Flow Meter is the embodiment of precision, efficiency, and reliability in cargo and pipeline applications. Its high accuracy, capacity, and resilience to extreme conditions make it the top choice for industries seeking confidence and excellence in the rapid transfer of large fluid quantities.

Have a particular application / project in mind? We’d welcome a call on +44 (0) 1189 169 420, or email us now at [email protected]

Why choose Rheonik Coriolis Mass Flow Meters? Unlike other Coriolis Meters, the patented Omega tube design of Rheonik Coriolis meters has solutions for operation up to 1722 bar (24,969 psi) line pressure at a precision of 0,05% and with renowned mechanical reliability. With highly accurate mass flow measurement performance and extreme capabilities, Rheonik meters are the ideal choice for many applications and quickly provide payback through improved product quality and greatly reduced maintenance. Whether used for transfer batching, process feed or control, Rheonik Coriolis Mass Flow Meters provide online precise flow and density measurement.

RHM 160 Specifications:

Nominal Flow (Qₙₒₘ)* | 30000 kg/min (66139 lb/min) |

|---|---|

Minimum Flow (Qₘᵢₙ)* | 750 kg/min (1653 lb/min) |

Operating Temperature | Fluid from -196°C to 120°C (-320°F to 248°F), see options in Part Number Code Ambient from -50°C to 80°C (-58°F to 176°F) |

Pressure Ratings | Up to 50 bar / 725 psi – dependent upon material |

Electrical Connection | Cable entry M25 x 1.5 (standard), M20 x 1.5, ½” NPT, ¾” NPT (optional) Max. cable length to remote RHE transmitter 30m / 98ft |

Sensor Enclosure Materials | Stainless steel (standard), 316 stainless steel (optional) Epoxy coated aluminium terminal box (standard), SS 316 terminal box (optional) |

Enclosure Type | Protection class IP66 / NEMA 4X with Standard Temperature Range (Option N1/NA); IP65 / NEMA 4 for Extended Temperature Ranges (Option E3) |

Wetted Materials | 1.4571 (316Ti), 2.4602 (Alloy C22) Additional/customer specific materials available upon request |

Process Connections | Nearly any – the RHEONIK AnyPipeFit Commitment. Consult factory for types/sizes not listed |

Pressure Rating Compliance | Europe – PED: Module B3.2+C2 |

Certifications / Approvals | ATEX / IECEx Approvals for zone 0, 1, 2 (suitably rated RHE transmitter required) North American Approvals for Class I, Div. 1, Groups ABCD (suitably rated RHE transmitter required) American Bureau of Shipping (ABS) Type Approval for use on marine vesselsATEX / IECEx Approvals for zone 0, 1, 2 (suitably rated RHE transmitter required) |

Documentation / Testing / Inspection | All sensors are hydro tested, calibrated and supplied with a traceable calibration certificate. Customized calibration and testing services available |

Project Docs / QA, Services | Rheonik offers a full set of services for large and complex engineering projects. – Certificates of origin and conformity, mill certificates |

Options | Enclosure heating for high temperature applications Cleaning for oxygen service Full service painting to project specifications |

* At Qnom pressure drop will be approximately 1 bar (14 psi) for H20. Sensors can be operated at higher flow rates but pressure drop will be higher. Maximum recommended velocity (liquid) through the sensor is 15 m/s. Beyond this point, cavitation may occur. Qmin is the recommended lowest flow rate. Sensors will measure flow rates lower than Qmin, but uncertainty may increase beyond 0.5% of rate.

These flow rate and pressure drop statements relate to standard pressure tube sensor versions. Models with higher pressure ratings have increased wall thickness and will have higher pressure drops and lower Qnom values.